Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayWhen you manage remote sites, monitoring critical assets like liquid propane (LP) fuel levels is a huge part of maintaining continuous operations and avoiding costly disruptions.

Recently, we worked with a telecommunications service provider to upgrade their remote monitoring systems. Their goal was to standardize monitoring across various sites, improve visibility into LP fuel levels, and receive proactive alerts for any issues before they could cause downtime.

This case highlights how solutions can be adapted to meet your specific needs and give you real-time data from remote locations. Whether you're dealing with fuel monitoring or other environmental factors, the right tools make all the difference.

To gain proactive visibility into fuel levels and prevent downtime, our client upgraded their monitoring system.

In remote environments, even a brief outage can have serious financial consequences. Continuous monitoring gives you a good way to avoid such disruptions by sending alerts when key thresholds are violated.

Dependable systems deliver real-time alerts, allowing you to respond quickly before minor problems become major ones. Remote telemetry units (RTUs), for instance, can monitor not only fuel levels but also environmental factors like temperature, humidity, and more.

Paired with the right sensors, the system monitors a wide range of conditions - including LP fuel levels. It then sends immediate notifications if anything falls outside acceptable ranges (the only way you'll know about problems in remote areas). These sensors, especially those that can be daisy-chained to cover large areas, are useful for performing this monitoring.

By sending SNMP traps, email notifications, or even SMS alerts, these systems provide actionable information that helps you reduce the likelihood of costly downtime. This kind of proactive monitoring is your secret weapon for managing remote sites and staying ahead of potential issues.

Our client faced a significant challenge: integrating a monitoring system at a site where the analog LP gauge differed from others they had previously upgraded. Consistency across sites was important, and they needed to ensure their new system could provide real-time visibility into fuel levels. Our engineer, Andrew, offered a practical solution:

"I believe you have this gauge. There appear to be commercially available replacements that support R3D (Hall Effect) sensing. Do you want me to work on quoting this for you? I would match all other aspects (like cable length) to your prior installations as much as possible."

Notice Andrew's response. It's important to tailor your technology to integrate with a variety of existing systems (which most companies already have in place).

Beyond integrating a new LP gauge, our client needed a system that could monitor both natural gas (NG) and liquid propane (LP) at the same site. This added complexity required a monitoring solution capable of handling hybrid fuel setups without compromising functionality.

Andrew further specified his recommendation by suggesting the Hall Effect Liquid Propane Gas Level gauge, which would work well with the client's existing infrastructure:

"The Hall Effect Liquid Propane Gas Level gauge will provide peace of mind by continuously monitoring your liquid propane fuel levels. I selected this gauge based on its similarity to the sensor models already used in your system."

This solution was ideal. These sensors allow continuous monitoring of LP fuel levels, providing reliable, real-time data and eliminating the need for manual checks (saving time and reducing labor costs).

By implementing Hall Effect technology, the client streamlined operations, making fuel monitoring at remote sites more efficient and less labor-intensive. The sensor also integrated well with their system for standardized monitoring across multiple sites, accommodating the unique requirements of their hybrid fuel setup.

Choosing the right equipment is critical to ensure new installations work smoothly with what's already in place (which avoids unnecessary headaches).

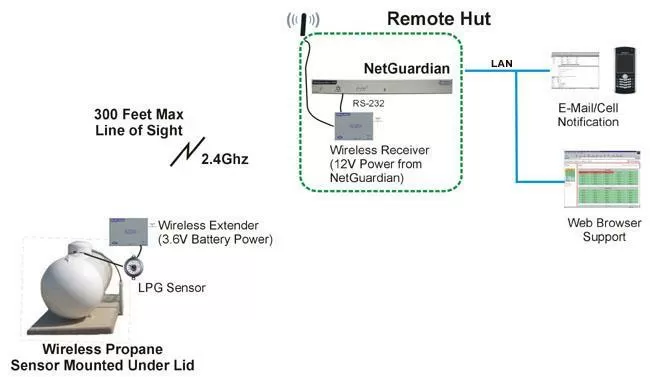

This is why the LP gas gauge wasn't the only technology recommended. An RTU from the NetGuardian G6 series was also integrated into the setup to provide discrete alarms and various analog inputs to monitor a wide range of parameters, including fuel levels, temperature, and humidity.

As your business expands, so do your monitoring needs. The DPS system's modular design allows you to easily scale your monitoring solutions as you add new sites or equipment. This was crucial for our client, who needed a monitoring system that could grow alongside their operations.

The NetGuardian 216 G6, already implemented in their system, provides a compact and scalable platform. This RTU supports up to 32 alarms, 6 analog inputs, and can expand further as needed (giving you room to grow). This RTU, as well as other RTUs from the NetGuardian G6 series, monitors a wide range of parameters - including fuel levels, temperature, and humidity. This versatility gives you the flexibility to meet the specific demands of each remote location and scale your monitoring capabilities at your own pace.

No two remote monitoring projects are the same, and you have unique requirements based on your specific operational needs. In this case, the telecommunications service provider needed a solution that not only monitored LP fuel levels but also integrated with their existing NG and LP infrastructure. Andrew's ability to recommend a solution that matched their prior installations, while offering upgrades, demonstrates our commitment to providing personalized service.

This tailored approach is what makes DPS stand out from other monitoring solution providers. Rather than offering a one-size-fits-all product, we work closely with you to develop customized solutions that fit your operational requirements. Whether it's matching sensor cable lengths to existing setups or configuring an RTU to handle a specific number of alarms, we're dedicated to finding (or creating) the right fit for your needs.

Whether you're managing a single site or a complex network of remote locations, DPS Telecom offers scalable, customized solutions to meet your monitoring needs. From real-time fuel-level monitoring to secure remote power management, our systems are designed to keep your network running smoothly and efficiently.

If you're ready to upgrade your monitoring capabilities and improve the visibility of your critical infrastructure, our team of expert engineers is here to help. Call us at 1-800-693-0351 or email sales@dpstele.com to get started with a custom solution tailored to your operational requirements.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...