Download our free Monitoring Fundamentals Tutorial.

An introduction to Monitoring Fundamentals strictly from the perspective of telecom network alarm management.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayGenerators are a key component of your network - whether they are used as a main source of power or as backup during a power failure. The bottom line is: your generators are critical.

Many companies often overlook monitoring their propane/diesel fuel levels. This means, at any given moment, you're vulnerable to running out of fuel and quickly into a power outage. With your uptime directly depending on your generators as a power source, it's simply too risky to leave such a high-value piece of equipment unmonitored. The network downtime you will experience leads to angry bosses and angry customers, angry customers lead to a loss in revenue. Don't lose revenue because of something that can easily be prevented.

Another potential issue is permanent damage to your equipment. When a generator runs on empty, you run the risk of the motor burning up. Typically this damage is not reversible, meaning you may end up having to buy a new motor - or worse, a whole new generator. This is a large expense that most companies simply cannot afford.

Here's an example for a propane tank. A similar solution is available if you have diesel tanks.

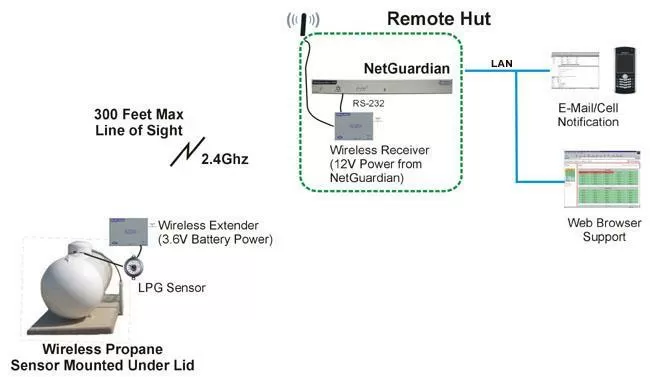

A common obstacle to getting visibility over propane tanks is a lack of a practical means of reporting the propane levels. Simply running cable all the way to an outdoor tank isn't feasible. Paying $800 for conduit and untold sums for trenching to install a $250 fuel sensor just isn't something everyone is willing to do.

One DPS client needed a better reporting method for their propane tank levels. We worked with this client to develop a wireless solution that could monitor their outdoor propane tanks with their NetGuardian RTUs inside a nearby hut.

Check out the Sensor Tutorial

In this application, the propane levels are checked once per day to ensure proper levels. However, if the power fails (and therefore the generator turns on), the propane levels are configured to be checked at a more frequent rate. This creates thorough visibility over fuel levels while conserving the battery-powered Wireless Extender.

This wireless sensor application means that there's no need to run conduit to the fuel tank. This saves money and provides isolation so the conduit doesn't act as a lightning rod directly to your tank.

The NetGuardian LPG Controller by DPS Telecom is one example of a wireless propane tank monitor. The new NetGuardian LPG Controller allows you to easily and remotely manage up to 4 liquid wireless propane gauges. With the LPG Controller, you can cycle through tanks - when a tank is close to empty, the unit closes the valve and the next tank valve is automatically opened. Through the web interface, the automatic cycling can be overridden and the user can take direct control if need be. LED displays on the front panel for each tank show the current valve status (open/close) and four threshold levels for propane level.

Convenient and automated management of smaller, cylindrical tanks so you can transport fewer quantities of propane at a time and still ensure full run time. This means you can cost-effectively refuel propane tanks when they are empty, rather than replace all of your tanks that are semi-full.

Each propane sensor (not included) is connected to the back panel of the Netguardian LPG Controller. In addition to monitor the propane sensors, the device also supplies power to each propane sensor. The NetGuardian LPG Controller is compatible with Rochester and other gauges.

Don't turn a blind eye to your fuel levels. Get more information about wireless propane monitoring or work with a DPS engineer to design a dream monitoring solution for your network...

For further information: See the section Tank Monitoring Knowledge Base.