Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayYour alarm monitoring application should work as a bridge between your current situation and future objectives. That's why a perfect-fit solution is so important.

No two networks are exactly alike, and your solution will be different than other companies' applications. You might need visibility of network equipment that you haven't been able to monitor until now, or you might need to merge all your network alarms into only one screen. The combination of variables is unlimited.

Most often than not, an off-the-shelf monitoring solution will not meet all your requirements. Make sure your potential vendor has the engineering sources to develop a perfect-fit monitoring solution.

We are specialized in alarm monitoring solutions for decades and have a wealth of experience, so we understand that - whatever your pain points are - the key is to have a unique solution that is simple for you to manage and keep an eye on. We also know that efficient, cost-effective perfect-fit solutions are only possible with vertical integration.

Let's dive into what vertical integration is, why it is important to help you get your unique monitoring solution, and how DPS vertical integration process works.

A company that adopts the vertical integration strategy is consolidating different stages of the production process and supply chain into their business. Vertical integrated manufacturers are also called "full-service" manufacturers.

The vertical integration strategy brings you three main advantages:

Purchasing network monitoring equipment is a big investment of your company's budget. It's important to have peace of mind when making this investment, so make sure the gear purchased is a high-quality solution for your company's monitoring needs.

No company clearly dominates the industry. However, even in this competitive market, some companies have established themselves more firmly than others.

So, ask your potential vendor how long the company has in the business, how many clients they serve, and how much they have grown.

Also, always check for testimonials and ask for references from their clients. Keep in mind that they might have clients that are facing the same problems and have to make the same decisions that you do, so a recommendation from them will be more valuable than any amount of advertising.

Financial stability means more in the technology sector than ever before. You want to be sure your potential vendor will be able to continue to support you for years ahead. Ask about the vendor's history and stability:

When you purchase business-critical equipment, you shouldn't pay for a solution that is unsatisfactory. Make sure to check whether the gear has a money-back guarantee, the length and coverage of warranties, and the amount of client support offered after the sale. Ask if the vendor offers technical support, training, and maintenance.

Remember: if the vendor doesn't have confidence in his product, neither should you.

The DPS perfect-fit engineering process usually begins when you access our website. You'll see a product that looks like it might work as a solution for your pain points, so you give as a call to learn more about it.

You'll have a customized consultation with our technical experts. They will ask you about the frustrations you're currently experiencing and what the perfect solution would look like. We've been in the market for more than 30 years, so we've seen all kinds of scenarios. Our few diagnostic questions will tell us a lot about your situation and they will help us understand all of your needs.

Our sales department works with engineering to develop a virtual prototype, a product summary, and a detailed sales proposal. Once you accept the no-risk proposal, our team kicks into high gear.

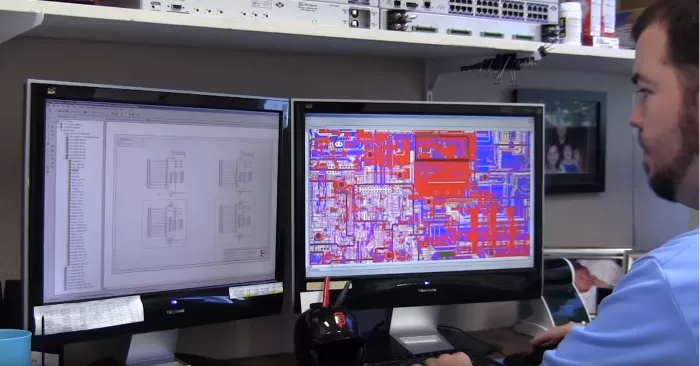

The engineers layout a schematic, a circuit board and a metal chassis for your new custom product. The manufacturing process begins as the metal designs are transmitted directly to our on-site metal shop.

First, a 50,000 psi water jet cutter (using a stream of water and Ruby garnet) will cut individual custom metal pieces out of a large metal sheet located just below the surface of the water. This works something like a metal printer, which allows us to to prototype metal pieces in hours instead of months.

After the cutting process is complete, the cut metal pieces are removed from the water jet. The pieces are cleaned with compressed air and then measured to make sure that they fall within the specified manufacturing tolerances. Once the additional steps of smoothing imperfections on the surface of the metal are completed, the flatwork is done.

Meanwhile, your new circuit board has arrived in our production department. The first step is to profile the board's temperature as it moves through the SMT oven. The next step is to prepare the board for part placement with a paste machine. A stencil is lowered down on top of the board. Once stencil alignment has been confirmed, solder paste is placed on top of the stencil.

After the paste is swept across the stencil, the prepared board is then populated with parts using an automatic SMT machine. Your board is now ready to run through the SMT oven using the temperature profile created earlier.

After that, the board now heads to wave solder. But, first, let's look back at our metal shop. When the flatwork is done, bending is about to begin. A press brake operator uses the program received from engineering to execute precision bends to transform the flat pieces into your new chassis.

Next, the bent metal is powder-coated. This is far superior to simple painting and will protect your new product in harsh industrial conditions. Once the powder has been applied, the metal must now be baked. After this is completed and the metal has been allowed to cool, it's taken to the hardware insertion station. Threaded attachment points are inserted into the metal allowing it to connect with other metal pieces and to the circuit board.

Back on our production floor, your board is prepared for wave solder as it passes over a standing wave of molten metal. All of the through-hole parts are soldered onto the board.

Now, your board moves to another station for final hand assembly. Back in the metal shop, it is completed in silkscreen metal and checked for fit. Then, carefully wrapped for transport to production. The metal shop work is complete when it delivers the finished chassis to the final assembly rack delivery.

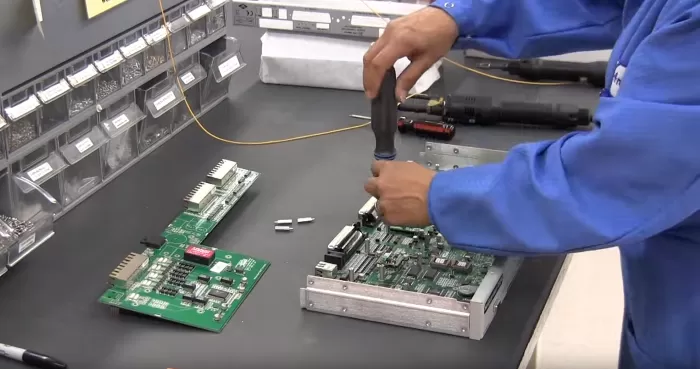

Delivery is also confirmed on the production schedule. The chassis is retrieved by the final assembly team and that's when your new metal chassis and your new circuit board become a finished product for the first time.

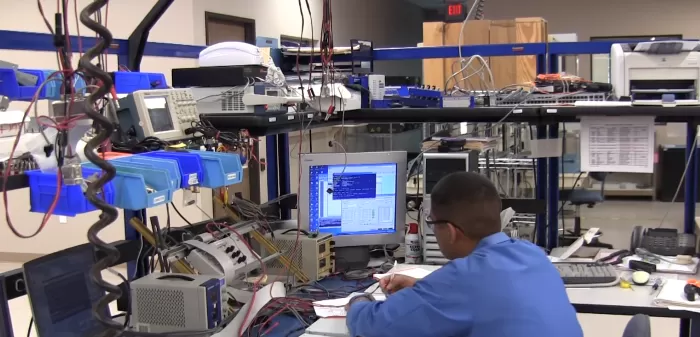

After assembly and a 12 or 24-hour burning process, your product is subjected to several automated diagnostics. These tests make sure that, when you get your device, it's going to work. Completed and tested products are retrieved to be prepared for shipment. Even our shipping boxes and foam designs have undergone testing and multiple revisions.

For one last verification, all products receive a final QA check.

Our perfect-fit engineering process quickly delivers the exact solution you need. And because it's built on a proven design with proven documentation, it'll practically jump out of the box and install itself.

If you think that a perfect-fit device is the best bet to eliminate your network visibility problems, then we are here to help you.

Using our broad product line, we aim to create a perfect-fit solution for your unique network. If you still need a better fit, we can engineer a totally new product made to meet your specifications - and it will be back by our client support.

Our main goal is to meet the needs of engineers and technical managers who implement network alarm management systems in enterprise networks. Treat us your personal engineering department and count with us to solve all your monitoring problems.

Morgana Siggins

Morgana Siggins is a marketing writer, content creator, and documentation specialist at DPS Telecom. She has created over 200 blog articles and videos sharing her years of experience in the remote monitoring industry.