Download our free SNMP White Paper. Featuring SNMP Expert Marshall DenHartog.

This guidebook has been created to give you the information you need to successfully implement SNMP-based alarm monitoring in your network.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayManaging unmanned sites effectively is one of the most important jobs in any company that has a network spread over a large geographic area. Whether you're a telco, power utility, railway, or any other company, a network monitoring system is essential to the day-to-day business operations. At many of those sites, you likely have a propane (LPG) generator as a backup power source. That generator is a vital failsafe in the event of a commercial power loss.

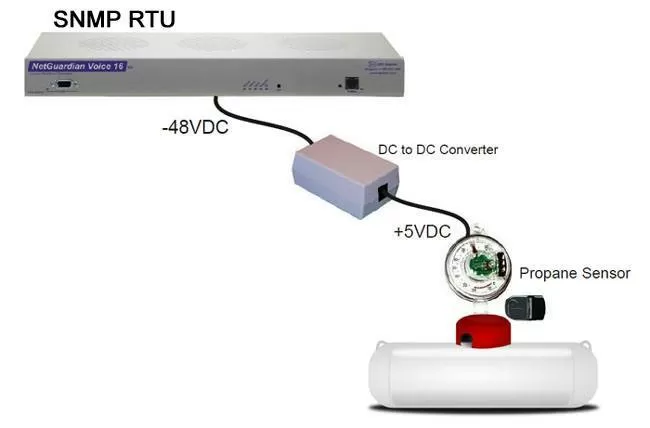

To minimize your risk of network downtime, you need some kind of monitoring and managing system for your remote propane generators. Simple Network Management Protocol (SNMP) already plays a major role in many companies. SNMP paired with a propane sensor gives you instant visibility on fuel level, and can alarm you when fuel levels cross critical thresholds.

Keeping track of your fuel levels prevents many issues. One potential issue is permanent damage to your equipment. When a generator runs on empty, you run the risk of the motor burning up. Typically this damage is not reversible, meaning you may end up having to buy a new motor - or worse, a whole new generator. This is a large expense that most companies simply cannot afford.

If you already have an SNMP manager, it makes sense to integrate your propane generator monitoring into your existing SNMP umbrella. Creating an entirely separate system that will require additional training and staffing, or that you'll forget about, could cost you both time and money with no guarantee of reliability.

The example above demonstrates propane monitoring without digging trenches or using conduits. Paying $800 for conduit and untold sums for trenching to install a $250 fuel sensor just isn't something everyone is willing to do.

Reliability is the most commonly overlooked necessity when looking for a good SNMP agent for monitoring your propane generators. Consider the massive investment you have in your network devices and the good-will you've established with your customer base. Don't sacrifice on quality to save a few bucks on the RTU that protects you from unexpected failures.

SNMP RTUs prices range from a few hundred dollars to a few thousand or more, so we're talking about a comparatively minor expense. Quality trumps price differences in this case. Remember that a single prevented incident will pay for just about any monitoring device several times over. Reliability is key.

But how do you know that an SNMP device for propane monitoring will be reliable? Consider the following:

The next thing you need to consider is the SNMP version(s) that the RTU supports. Has your company standardized on supporting SNMP v3 for security reasons? Do you need any of the more advanced SNMP message types that were added in version 2? A really good RTU will let you choose between several SNMP versions with a user-selectable option.

Finally, you need to know what kind of architecture will exist between your central office and your propane generator. How, exactly, will alarms and control commands travel between those two points?

When developing a network management system, SNMP will likely be your protocol of choice, but what about transport? The most common choice is a LAN connection. However, some sites, have T1, PPP/Fiber, or FrameRelay/Fiber.

With the right RTU, you can natively use that other transport to send SNMP traps. Cellular/wireless modems are also an increasingly popular option, whether as primary transport or as a backup in case your primary LAN fails. We offer different builds of our RTUs to accommodate a multitude of modes of communication.

Now that you have communications with the RTU, how does the RTU talk locally with your generator and propane tank at the remote site? You can always simply wire discrete/analog sensors directly to the generator, but they're frequently quite a distance from the building itself for multiple reasons. In that case, the cost of digging a trench and laying conduit can become prohibitive. For this reason, we offer several wireless solutions for transmitting your sensor readings to an RTU.

As you can see, there are a few important options when choosing an SNMP-based propane monitoring system for your remote site. However, if you can get these right, you've set yourself up with a very sustainable remote monitoring and control system.

For over 30 years, we have specialized in remote network monitoring and have built numerous RTUs that support SNMP. We manufacture all our devices on-site at our only campus in Fresno, California. Our RTUs and even our custom sensors are encased in hardened metal chassis and are built to last. More than that, we offer free tech support for all our devices, whether or not your warranty is active.

At DPS, we are committed to helping provide the solution to your networking monitoring problems. We make it easy to integrate propane sensors into your existing monitoring solution, giving you visibility into fuel levels for when your backup power needs to come on in a moment's notice.

As a backup, generators may sit for long periods. If you don't actively monitor your propane levels, your generator might not work when it is needed the most. With the Propane Level D-Wire sensor from DPS, that is no longer a threat. Using this sensor, you will know as soon as your propane level drops below a certain threshold. Plus, using a propane level sensor can help detect equipment problems, such as tank leaks. Tracking propane usage rates will allow you to spot irregularities that may signify a leak in your tank.