Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayMany different organizations, in many different industries and applications, deploy remote telemetry units (RTUs) to monitor and manage their processes.

That's because RTUs are rugged industrial computers designed to withstand the conditions of an industrial environment. Through inputs and outputs, they allow network technicians to monitor and control just about any piece of equipment at even the most remote sites.

We are an experienced remote monitoring systems provider and have designed and built hundreds of different RTU solutions for multiple clients. With that being said, nowadays see a big increase on the number of companies that are looking to automate their production processes, which leads to data-driven and more informed decisions.

In manufacturing industries, RTUs are usually deployed to maintain the health of machinery and ensure network uptime. But that's not all. RTUs have multiple roles in manufacturing applications, and if you work with a manufacturing network manager it's important that you know why. So, let's dive in.

An RTU is a device used for remote monitoring and control of multiple different equipment and systems. Normally, it's deployed in an industrial environment where it serves the same purpose of a programmable logic controller (PLC) but in a higher level.

RTUs are located near the monitored process and monitor analog and digital values via sensors and data received from connected equipment (such as a switch, thermometer, or relay). Then, it will send this information to a central master station.

In addition to monitoring input data and sending it to a master station, remote telemetry units can also control many functions and processes, such as switches, pumps, and even doors. This means that output device receives commands from the RTU to execute a specific function.

For instance, a sensor can let your RTU know that the pressure in a line is too high. You can tell your RTU to send a command to a valve to open, reducing the pressure.

Automatic control can also be featured in RTUs. So, for example, your unit can automatically turn on a generator in case of a commercial power failure to maintain your manufacturing operations going.

The most efficient RTUs offer intuitive web interfaces that will display real-time information about your network. So, without even being on the facility, technicians can access your network. This allows you to make configuring your system, acknowledge alarms and send out commands without having to drive to your facility.

Also, the ability to receive instant alarm notifications allows your technicians to act quickly in response to problems, which can reduce downtime and costs.

As we've talked before, RTUs monitor and gather data from connected inputs and machinery. Because of that RTUs are commonly used in SCADA systems to gather and display useful information.

Supervisory Control and Data Acquisition (SCADA) systems are used across many industries to remotely monitor and automate the control of industrial processes and machines. SCADA systems reach this goal by integrating your network, RTUs, sensors, and equipment to gather, analyze, translate and present real-time information.

So, instead of manually performing measurements and adjustments, you can automate these tasks with SCADA systems. This will give you many benefits, such as minimizing human error, storage and backup of data, and a secure alarm monitoring system.

SCADA RTUs can detect problems in the network and quickly issue commands to avoid downtime. But if an outage were to happen, RTUs will immediately alert your techs - allowing them to identify the location of the failure and take appropriate action.

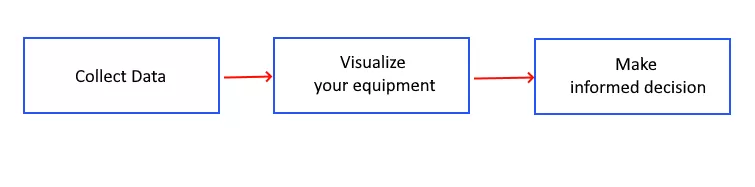

Remote monitoring systems are only as useful as the actionable insight they provide. This means that the collection of information has no purpose unless it's organized and accessible in a manner that allows you to have insight over your network.

So, instead of getting caught up in simply managing the incoming information, it's important to analyze this data. But, this can be too daunting if you a big network. In fact, the data-rich nature of remote monitoring systems tends to prevent techs from leveraging the system to its maximum potential. Advantages that could be acquired by a simple analysis are often lost in the middle of the overwhelming income of data.

That's why it's critical to have a monitoring device that can do system analysis for you.

Every competent RTU should have a reporting tool that is capable of evaluating the information to predict the root causes of alarms and other irregularities.

This means that you are able to study production data collected by your RTUs in order to find patterns, which enables you to make predictions and decisions. The result is a system that can provide predictive maintenance and remaining useful life information to prevent downtime, propose a response to issues that might occur, and improve quality control with based on production insights.

That's why it is critical that you make sure your RTU has analog trending capabilities built into its interface. An interface that provides you with analog graphing is the best practice here, it gives you a visual representation of your data and makes problem areas stand out.

The bottom line here is that with the SCADA data collected by RTUs, your technicians are able to better analyze your production performance and make concision decisions to enhance efficiency and bottom line.

RTUs are supposed to be versatile solutions for any type of industry. This means that, if these devices are designed properly, collecting data and controlling gear can be done the same across different companies.

During the process of choosing your ideal RTU, it's important to take not only your needs now but also your future requirements. Your solution has to be able to meet most of these needs to enhance your competitiveness, increase your productivity and decrease your total costs.

The following are some of the points you should keep in mind when choosing your RTU.

Using a multiprotocol solution ensures a smooth integration of your different system equipment, giving you better flexibility and maintain versatility.

RTUs that can only work with one determined communication protocol are just a waste of time and your company will spend a lot of money to make it fit into the current network. So, don't forget about the communication with your existing hardware.

RTUs are a long-term investment that will impact your manufacturing processes for years to come. It's important that you take into consideration the possibility to upgrade your RTU's firmware, how much does it cost and so on.

Many companies profit from after-sales services, such as upgrades, training, and tech support. They know that you will need these services in the future. However, it's possible to find vendors that include these services in the base affordable price.

It's also critical that your RTU is able to support future expansions. So, having some more capacity than what you need right now is important.

Secure access is embedded in any efficient RTU. It should protect your network from unauthorized users, hackers and other threats.

Make sure your vendor is able to design a device that can meet your needs 100%, such as capacity, preferred protocols, interface, and notification alerts. Having a perfect-fit solution means your RTU will integrate smoothly into your current network and give all you need to improve your bottom line.

The bigger the provide is, the harder it is to have special needs attended though. So, it's always better to choose smaller or mid-sized proven companies - they are the most likely to meet your requirements.

Buying your RTU is just the beginning. You need to think about services like your gear's installation, staff training, tech support, and maintenance. And make sure that these services are either included or at least known of their price.

Even with new technologies being developed every day, RTUs will continue to play an essential role as a processor of real-time manufacturing information. They are a vital piece of gear that will guarantee the uptime of your operations.

However, in order to achieve your desired goals, you need to choose your remote monitoring equipment wisely. The first step is to find a vendor that you actually trust.

Located at Fresno, California, DPS has over 30 years of experience designing and manufacturing high quality and reliable remote monitoring systems. With all our applications done in our headquarters, we can control each step of our design and manufacturing processes.

In addition to designing and manufacturing remote monitoring solutions, our services include training, tech support, and system maintenance. So, our relationship won't end after the sale. Our objective is to provide you with a perfect-fit solution that will improve your bottom line.

If you'd like to know more about RTUs, remote monitoring or our solutions, just give us a call. Our team of experts will help you improve your efficiency.

Morgana Siggins

Morgana Siggins is a marketing writer, content creator, and documentation specialist at DPS Telecom. She has created over 200 blog articles and videos sharing her years of experience in the remote monitoring industry.