Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayA PLC (Programmable Logic Controller) is like a mini computer. These devices control machines and processes in places like factories. It's made to handle conditions like extreme temperatures, electric interference, and shaking, which are common in industrial settings.

A PLC works by gathering information from different sensors. It then follows pre-set instructions to control a process or lets you know what's happening so you can make changes. Because it's controlled by software, it's easy to change how it works. This makes it both flexible and cost-effective for managing different tasks.

In this article, I'll explain more about how PLCs work, how to program one, and potential alternatives to these devices. Picking the right tech will boost how well things run, cut down costs, and make everything more reliable, leading your projects to success.

Imagine a PLC is like the brain that tells factory equipment what to do and when to do it. They collect real-time data to make sure everything runs smoothly. To do so, they check on things like how long a device has been running, the temperature, and how much it's being used.

To make sure everything in the process is working right, a PLC checks data from different sensors. It then uses its programmed instructions to decide what action to take. For example, it may adjust the machine or give real-time updates to help you make quick decisions. This is all done with software, making it easy to change things up fast and without spending a lot, to keep up with new needs.

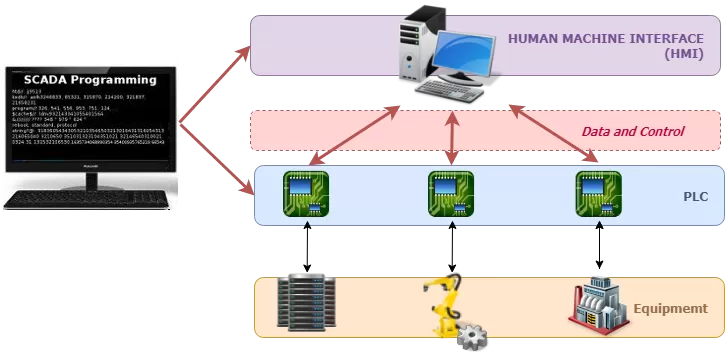

PLCs are great at making automation smoother and making operations run better. They're also made to work well with other control systems, like SCADA, which helps manage and gather data. Through something called a Human Machine Interface (HMI), people like operators or managers can interact with the PLC in real-time. Operators and users can use the dashboard to watch and control the industrial activities and machinery.

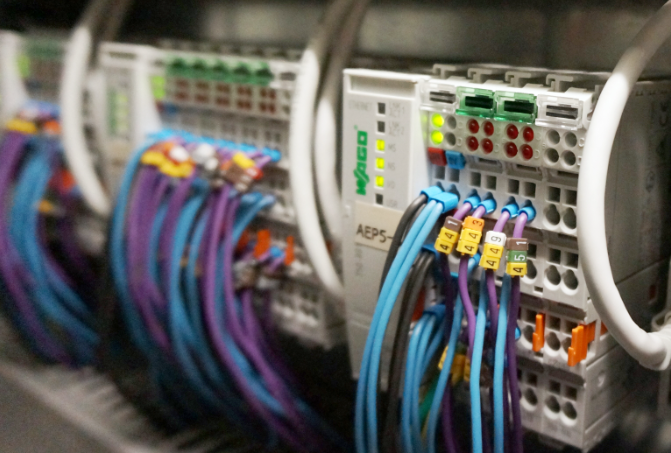

PLCs are made up of several parts. The key components include:

The components of a PLC work together to automate and control industrial processes. At the core of the system is the CPU, which executes the control logic stored in the device's memory.

I/O modules facilitate interaction with external devices. They receive inputs and send outputs to control various operations. The power supply ensures all components receive the necessary electrical power.

At the same time, the communication interface allows the PLC to connect with other systems for monitoring and control. All these components are typically housed in a chassis or rack, providing a compact and organized structure.

PLCs are no longer standalone automation tools. They're integral parts of complex, interconnected systems that demand smooth communication and interaction. The need for flexibility, scalability, and real-time responsiveness in industrial processes has driven this evolution.

Modern PLCs utilize advanced communication protocols such as Modbus, Ethernet/IP, and Profibus to interface with other devices and systems. These protocols enable real-time data exchange between the PLC and input/output devices, SCADA systems, and even cloud-based platforms. This connectivity allows operators to monitor processes remotely, reduce downtime, and enhance operational efficiency.

Input and output (I/O) devices serve as the physical connection points for PLCs, allowing them to gather data and control equipment. Inputs include sensors that measure parameters like temperature, pressure, and flow rate, while outputs drive actuators such as motors, valves, and lights. By integrating intelligent I/O modules with communication capabilities, PLCs can achieve distributed control. This improves system reliability and simplifies wiring complexity.

Integrating PLC systems with a strong communication network transforms how industries operate. For instance:

With these advancements, PLCs remain at the forefront of automation, bridging the gap between traditional equipment and modern, IoT-driven industrial environments.

The average price of the device itself sits around $100-$200. The thing that is more costly about using a PLC is the time required to manually program each unit.

These are best used when there are many machines working together. For example, in factories with many moving parts. However, PLCs can also be used for smaller scale projects like controlling home automation systems.

Here's a list of facilities where PLCs are commonly deployed:

By integrating PLCs or an alternative system (like an RTU), you can increase operational efficiency, safety, and reliability.

You can program a Programmable Logic Controller (PLC) in different ways. Ladder logic is the most popular language for programming them because it looks like electrical circuits. This makes it easier to understand and visualize how things work in the PLC.

Having that advantage makes controlling processes simpler. Besides ladder logic, there are other programming languages that let you customize and design control systems, offering flexibility in how you set things up.

Programming languages commonly used for programming Programmable Logic Controllers include:

Different PLC manufacturers may support different programming languages, so the choice of language may depend on the specific PLC model and manufacturer's software environment. Additionally, some PLC programming environments may support multiple languages, allowing programmers to choose the most appropriate language for their application.

Memory and storage management in a PLC determine how efficiently it can execute control programs and handle data. Memory management saves and organizes critical data to make sure information is retained. The types of Memory in a PLC include:

Volatile memory is used for temporary storage while the PLC is running. It stores data related to the current operation, such as the values of inputs and outputs, timers, counters, and intermediate results of calculations. Since RAM is volatile, all data is lost when the power is turned off.

Non-volatile memory is used to store the PLC's firmware and the control program (ladder logic or other programming languages). Because it is non-volatile, data in this memory is retained even when the power is turned off. Flash memory is often used for program storage because it allows easy updates and modifications to the control program.

EEPROM is another type of non-volatile memory used in some PLCs to store user programs, configuration data, and settings. Like flash memory, it retains data without power and allows for reprogramming without needing to remove the memory module.

These memory types are managed via:

Overall, memory and storage in a PLC are carefully managed to maintain reliable operation, data integrity, and the ability to update or modify control programs as needed. This management is needed for maintaining the performance and longevity of PLC-controlled systems.

The life cycle of a PLC is a comprehensive process that verifies the system is designed, implemented, and maintained effectively to meet the demands of industrial automation. Each stage plays a crucial role in the overall performance and longevity of the PLC. The stages of their life cycle are:

By following these stages, a PLC can operate reliably and efficiently, adapting to new requirements and technologies as they emerge.

If all of that sounded like a foreign language to you, but you still need a way to monitor and control your remote gear, you're in luck. There are solutions that don't require a tech-savvy programmer to implement.

For individuals or industries seeking alternatives to programmable logic controllers (PLCs), the following options can offer simplified or tailored solutions for managing and controlling automated processes:

Each of these alternatives to PLCs comes with its own set of features, benefits, and best-use scenarios. You'll want to assess the specific needs of your project or operation before making a selection.

Many of these solutions work better for small-scale projects, and for someone with advanced programming skills who is able to program the device for monitoring and control.

If you're looking for something simpler than the complex and code-heavy PLCs, Remote Telemetry Units (RTUs) might be just what you need. One of the greatest benefits of an RTU is that it is pre-configured, making them easy to implement and roll out at multiple sites, even without highly technical staff.

RTUs are great for collecting and sending data from unmanned sites, straight to a central system that controls everything. Unlike PLCs, which are good at controlling processes and automation, RTUs focus more on monitoring equipment and conditions from afar.

They're vital in industries like oil and gas, water management, and electricity distribution: anywhere you need to get real-time updates from equipment spread out over large areas. RTUs connect to sensors to pick up important info (temperature, pressure, how much of something is flowing, etc.) and then send this data using different ways of communication. This helps businesses run more smoothly, plan maintenance before things break down, and make better decisions, all with no programming required on your part.

Choosing between a Remote Telemetry Unit (RTU) and a Programmable Logic Controller (PLC) boils down to what your specific needs are. RTUs shine in scenarios where the primary goal is to monitor and collect data from various locations, especially those that are remote or difficult to access. Here are some key benefits of opting for an RTU over a PLC:

When deciding between an RTU and a PLC, consider what's more important for your operation: the complex control and automation capabilities of a PLC, or the straightforward, robust monitoring and data collection features of an RTU. For many, the simplicity, remote capabilities, and reliability of RTUs make them ideal for keeping tabs on far-flung operations without needing deep programming knowledge.

The choice of which device to choose is often confusing and conditional. Here at DPS, we are happy to provide personalized consultations in order to determine your needs.

The objective of our consultations is to find a long-term solution to your SCADA needs. Let us help you be proactive in your search to find effective remote monitoring systems at the capacity which will best fit your company.

If you would like more information regarding how you can decide on and implement the best equipment for you, give us a call at (800) 622-3314 today.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 18 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...