Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayYour sites and facilities house important mission-critical gear which require advanced controls to maintain comfortable temperature and humidity levels while staying efficient and reliable. Because of that, multiple companies from different industries have direct digital control (DDC) systems. These DDC systems are necessary for precise HVAC control and efficiency.

Skip this article and:

- See our direct digital control (DDC) system

- Download our SCADA Tutorial PDF

DDC systems allow you to have precise control over your HVAC units, which provides you with the ability to configure different temperature zones, schedule and automate system operation, and monitor performance over time. This is why direct digital control HVAC solutions are so popular among facility managers.

As remote monitoring systems manufacturer, we delivered multiple solutions to many clients that integrate DDC systems with Supervisory Control and Data Acquisition (SCADA) systems. This way, monitoring and controlling your various applications become possible. DDC systems work particularly well when paired with SCADA for maximum efficiency.

If your sites are not equipped with a direct digital control system, keep in mind that this can be a worthwhile investment. So, let's take a look at what exactly these systems are. Understanding what DDC is can help you decide whether it fits your operational needs.

Direct digital control system can also be referred to as building automation system, building management system, and energy management system. For HVAC applications, DDC systems offer unparalleled control.

What is DDC? Well, DDC refers to the automated control of a process by computers and microprocessors with sensors. This is the core of what makes direct digital control HVAC solutions so effective.

Direct digital control systems give building owners a higher level of control over their mechanical and electrical systems. The most modern systems can also offer the trending analysis feature. This can be used to increase efficiency and to pinpoint issues with your equipment. When evaluating DDC controls basics, this feature stands out as a key benefit.

DDC systems transmit information over the internet for remote monitoring and control capabilities. This ensures that DDC HVAC systems can operate efficiently in diverse environments.

DDC systems have a central master station that will give you information about your HVAC units or anything else you wish to monitor in one single screen for efficiency. The information will be brought to your master station via sensors that will be deployed at your facility. Once you receive the data, you'll be able to monitor performances, remotely control equipment, and make operational adjustments when necessary. This makes direct digital control HVAC integration easy for most facilities.

DDC systems usually allow for a high level of flexibility. Meaning that, although their primary purpose is building automation and systems integration, they also make it possible for your technicians to react to problems that may arise at your sites, troubleshoot issues, and take care of maintenance tasks from a single point that gives the network-wide visibility. For those wondering what DDC is capable of, this flexibility is a defining feature.

Just like in SCADA systems, DDC utilizes proprietary or open communication protocols to transmit data from device to device. Some protocols used in DDC systems include Modbus, BACnet and Lonworks.

DDC systems offer many advantages for company owners, maintenance technicians, and network managers. An efficient DDC system will:

In a nutshell, direct digital control systems will save you money in the long run while giving your technicians better control and situation awareness over your network. DDC controls basics emphasize cost savings and operational efficiency.

If you are the technician responsible for the remote site's HVAC system, you are probably primarily concerned about the DDC system and HVAC units. However, many companies don't have many technicians to take care of each part of a remote site, many companies have a small group of people responsible for monitoring multiple sites. This is where direct digital control HVAC solutions integrated with SCADA come into play.

A best practice is then to integrate your DDC with a SCADA system. In reality, even if you have dedicated personnel for each facility, integrating both systems is still a good idea as it will allow you to remotely monitor and control other important equipment. This integration enhances the capabilities of DDC systems significantly.

When integrating your DDC system with a SCADA system, you'll not only have sensors but also Remote Telemetry Units (RTUs) as well. These devices will allow your staff to keep an eye on your HVAC system performance in real-time, and when there's a problem RTUs can automatically take action according to user-defined settings.

So, in addition to controlling the HVAC system, the SCADA system will also give other capabilities, such as data gathering, monitoring, and identifying trouble spots for virtually any building function. The following are some examples of what can be monitored with a SCADA system:

With integrated DDC and SCADA systems, you or your techs can manage any aspect of your remote sites from your own desk - avoiding telecom truck rolls. Some important features that a SCADA system can give you include:

If integration is not an option for you, for any reason, keep in mind that a SCADA system is normally a better choice than DDC controls. When high availability and high performance are your main priorities, a SCADA system is the best direction to take.

SCADA systems are usually designed to meet industrial specifications, while DDC systems are mainly used commercially. So, the bottom line is that, although both DDC and SCADA systems can make decisions based on sensor data, SCADA does it faster and more reliably.

DDC automation controls combine hardware and software to mainly control facilities. Efficient DDC systems will ultimately help you save money on energy consumption. SCADA does the same, but in a higher level of precision and reliability. Direct digital control HVAC systems also complement SCADA when tailored to specific needs.

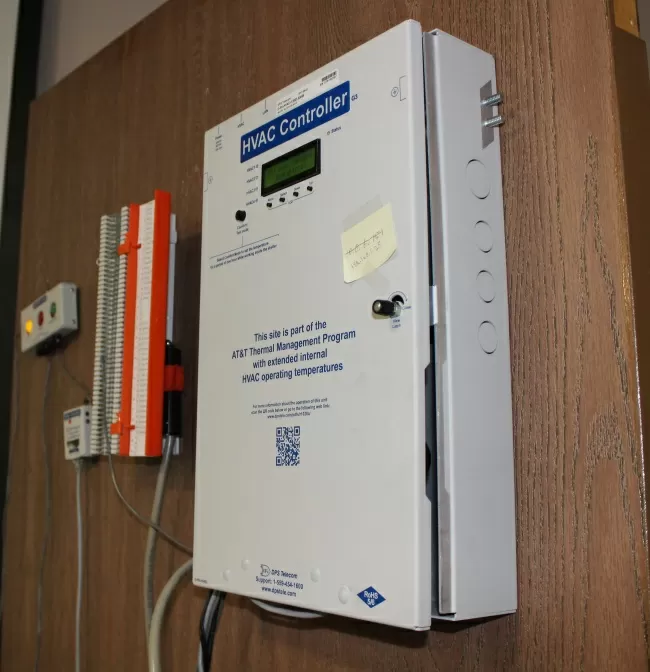

So, if you've decided to go with a SCADA system, then you need a competent device such as the HVAC Controller. This ensures you get the most out of your DDC HVAC system.

The HVAC Controller is a device that allows you to efficiently control your HVAC systems to run at an optimal level - even automatically making adjustments when needed.

And as a vertical integrated manufacturer, we can actually evaluate what would work best for your needs according to your unique network. This way we can develop custom-designed devices for our clients that will meet their requirements 100% and benefit their operational demands.

So, if you want to know more about the HVAC Controller and it can meet your network needs, just send us a message.

All DPS Telecom products include comprehensive technical support. If you've purchased one of our products and are encountering any kind of issue, contact DPS Tech Support today at 559-454-1600.

At DPS Telecom, the representative who answers your call isn't an intern reading from a script. DPS Tech Support representatives are engineers who contribute to product development. And, if your problem requires additional expertise, the DPS Engineering Department that designed your product is right down the hall.

Help us connect you to the right engineer by filling out this quick questionnaire. Simply leave your contact information to get started, and we'll call you back. Most preliminary discussions are about 15 minutes, and afterward, we'll send you a custom application diagram of a recommended solution that'll make it easier to justify your project to management.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...