Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayThere's no more common sensor on our RTUs than temperature sensors. In fact, the majority of our builds have one built right on the board to give you a good ambient reading of the temperature in your site.

I recently had an email exchange with a DPS client. He had questions about the specific architectures and I/O we use for measuring temperature. I think that conversation will be useful for you as you research your options for remote site temperature measurement.

My client asked me:

"If the temp sensors are D-wire (Dallas One-Wire), then why do they require an analog input? One-Wire is digital. Are you using the analog inputs as bi-directional digital comms channels to communicate digitally with the sensors? I've seen similar things being done with Arduino controllers, so I guess it is common practice."

I responded:

"The D-wire temperature sensors do not require an analog input. The analog value is digitized at the sensor as you described. The NetGuardian 420 has analog inputs, but you will not need them for D-Wire sensors."

Next, my client asked:

"Ok, that answers most of my questions but what about the 4 dedicated analog inputs for temp & batt volts?"

I cleared everything up by explaining:

"The 6 traditional analog circuits are in essentially the same state on the NetGuardian 420 as they always were: 2 are internally tied to power inputs to monitor them, 1 is tied to internal temperature sensor, 1 is tied to pluggable port (looks like headphone plug) for traditional external analog sensor, 2 are available for your general use via back-panel connector.

This has not changed in the D-Wire era. The internal temperature sensor remains on the 420, and many people choose to use only that sensor if they're not very worried about temperature. Although it cannot be placed away from the 420, it's a good general ambient temp reading. The D-Wire port has had the effect of making our traditional external temperature probe less common. If people want an external sensor, they'll tend to use a D-Wire sensor.

As a result of the above, you'll have 2 general analog inputs for any purpose AND an internal temperature sensor on the 420 AND an external D-Wire temp sensor. You could add many more D-Wire sensors of various types later if you like and add them to your daisy chain."

As you can see, there are many different kinds of temp sensors you can use. This is the result of different approaches across time (and among manufacturers).

Temperature sensors have evolved across time, generally trending toward being better and cheaper. Where it was once common to have just a single ambient sensor in a room, you can now install sensors at troublesome "hot spots" to track those temperatures specifically.

Let's take a look at key developments of sensor and related RTU developments at DPS. I think of us as a bit of a pioneer in this space in some cases, but you should know that many of these evolutions reflect the broader monitoring industry.

Location, location, location. It's as true for sensors as it is for business. Where you put your sensors matters.

You can have an RTU with a built-in ambient sensor. Where you place that one is pretty obvious, although you do have the freedom to choose a location, usually in a 19" or 23" equipment rack, for the RTU itself. Although you might see some heat from the RTU itself, and your critical equipment might be farther away and not directly measured, this sort of sensor is WAY better than nothing.

You can also have an external sensor with some location flexibility. In my email exchange above, you saw me talking about our external probe with a 7-foot (about 2 meters) lead on it. That connects via a stereo-type plug to the NetGuardian 832A G5 and several other NetGuardian models. The same placement freedom is possible whether you're using analog (like the 7-foot probe) or digital (like the D-Wire sensor) communication to the sensor itself.

What D-Wire gives you, in terms of placement flexibility, is the ability to customize your wire length. D-Wire supports runs of potentially several hundred feet/meters, depending on the sensor and RTU. You can also daisy-chain multiple sensors without having to run them all back to the RTU.

D-Wire also means that you can "place" a temp sensor by virtue of installing a combo unit that measures multiple different things. The two most common that DPS sells are: Temp+Humidity & Temp+AirFlow. These two sensors are excellent for assessing either weather conditions and possible water accumulation - or the performance of your HVAC system.

Let's now consider the key elements to consider when choosing a temperature sensor for any remote location:

Of course, everyone know that a temperature sensor measures the nearby heat level. There's a lot more to consider than that, however.

I had an exchange with a government contractor via email recently about a bid from a big-name agency. This is the kind of household-name organization with ultra-strict security and uptime requirements. I could tell you more, but I'd have to... well... you know.

I'll tell you what: let me tell you half and then maybe just rough you up a little.

Here's an email exchange I had recently with a government contractor:

"Andrew, I'm having trouble finding the part number D-PK-MODBX-12016. Are you able to provide a quote for this item, Qty 3?"

DPS sells direct and frequently creates new products, so contractors often struggle when first calling their typical distributors. I replied:

"We sell the MODBX to a pretty select group of customers (it was developed for one in particular), so I have more insight into the use case than is probably typical for a manufacturer. I'm a bit concerned by your request for: D-PK-MODBX-12006. Although we initially sold that to our primary customer for the MODBX product, we later settled on a package that also includes two AC wall transformers and a temperature+humidity sensor. That package is: D-PK-MODBX-P0001.00003. I've emailed the end user to clarify, but there is a large time difference. I haven't heard back just yet. Do you have any insight into this? I'm happy to quote you whatever you'd like. It won't do either of us any good to quote something that doesn't do the job."

My client responded:

"Thanks for the information/insight! I've reached out to the end user and asked if they want to go with the previous MODBX requested or the new package that includes the wall transformers and sensor. As soon as I hear back, I will let you know how they want to move forward. Thanks again for your help!"

Then, later:

"Andrew,

The customer came back and stated that they need the bundle part: D-PK-MODBX-P0001.00003."

As you can see, temperature monitoring is taken very seriously in large, important organizations.

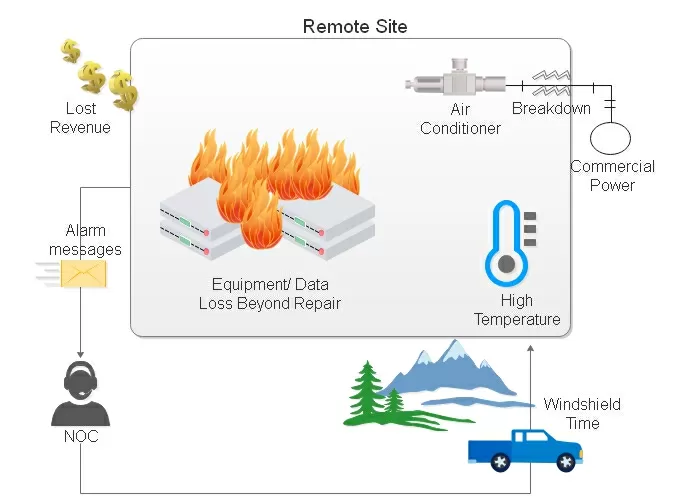

If you want to remotely monitor temperature at a remote facility, it's a fair bet that you want to (or should want to!) monitor other things at that site, too.

You have important equipment that deserves good monitoring. This can include self-reported device failures, but also environmental levels like humidity, air flow, hydrogen accumulation (from batteries), and water leaks.

You really need to be working with someone who has done this before.

Fortunately, DPS experts are available at no cost to you. Of course, we hope you take a look at our sensors and RTUs, but that's ultimately up to you.

Give me a call at 559-454-1600 to get started. You can also email me at sales@dpstele.com

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...