Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayNot too long ago, a potential client from an overseas country reached out to me about monitoring solutions for his pump rooms and pump sets. He had over 2000 pump sets and was in the process of developing and upgrading all of them.

A pump room is responsible for pumping any required fluid to the area that it needs. This process should always be automated with the right type of alarm monitoring systems in place. These rooms also serve as a control system for pumps throughout the facility and include pump sets.

These pump sets come in two different hierarchies:

Primary pump sets are responsible for pumping the fluids from the central pump room. Secondary pump sets are located at specific points throughout the facility to receive liquids from parent sets and distribute them to specific areas.

These pump rooms work well hand-in-hand with alarm monitoring systems such as remote telemetry units, master monitoring stations, and everything in between. This is because they are centralized rooms that are responsible for monitoring, maintaining, and controlling the fluid flow throughout a facility.

Since pump rooms and pump sets have a lot of moving parts and operations, however, something needs to monitor them. This is where alarm monitoring systems come in. If you are someone who is prospecting solutions for your pump room or pump sets, you are probably looking for remote monitoring of equipment status such as:

Remote monitoring capability of your pump's run status is crucial. This is arguably the most important aspect of monitoring your pumps. You can tell your run status through:

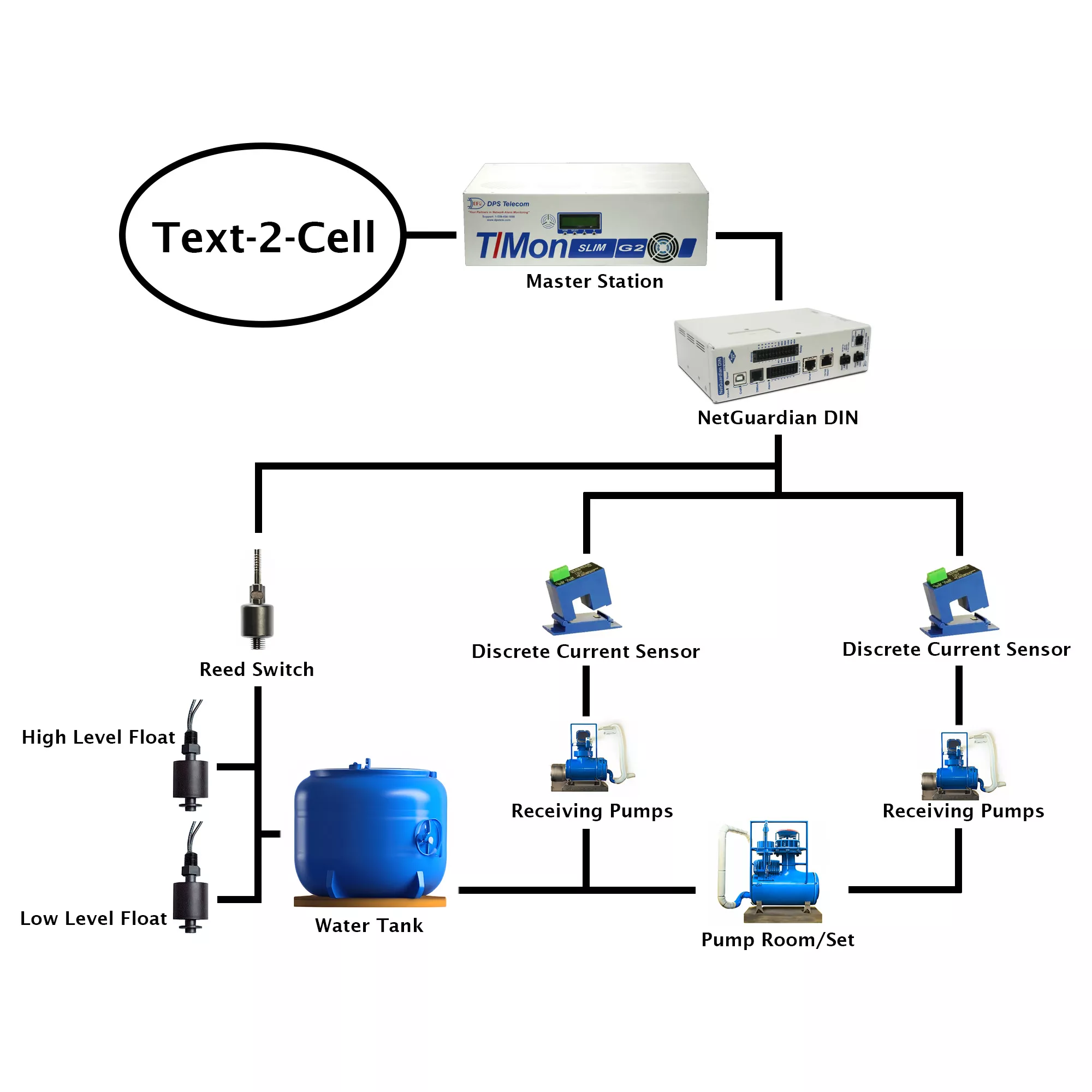

You can also use an RTU such as a NetGuardian to monitor the power coming from a pump. When a pump has an active current, you can loop 1 phase of power from it through a discrete current sensor that opens and closes depending on whether a current is flowing or not.

A discrete alarm would then be monitoring the sensor itself through a NetGuardian RTU to know if there is a current (open contact), or if there is no current (closed contact)

The fault status of a pump system would trigger an alarm. This would stop the pumps if your system is configured correctly depending on the situation. What happens when an alarm is triggered should be completely customizable by you if you are working with a good alarm monitoring system manufacturer.

In this state, you should also be equipped with a Text-2-Cell or Email capability that is sent out to your in-house maintenance crew. My client requested this directly, and I let him know that I was more than capable of providing him with it.

A facility would need to pump water to various locations throughout due to multiple reasons. An easy and quick reason that comes to my mind is protecting other systems from overheating. This means that monitoring your water tank's level is crucial.

You can monitor your tank level by installing tank sensors within the storage that are attached to a float (aka Discrete Liquid Level Sensor) that moves up and down a stem depending on the water level. This float would contain a small magnet, while the stem that the float is attached to has a dry reed switch.

When the magnet passes over a certain spot on the stem, the reed would then magnetize and a circuit would complete when contacts come together. The circuit completing would energize an alarm that enables you to know when your tank water level is too low. There are some installations that I have seen DPS Telecom do which have included a float for when a tank's water level is too high.

My client had initially reached out to me with a primary need for Text-2-Cell capabilities. To help his specific needs, I asked my client if his pumps already had relay outputs to trigger alarms and how he was getting his fault status from the pumps.

My client told me that he was working with a starter panel already. He told me that he needed one, so I knew I was going to recommend a NetGuardian DIN. The DIN is a small industrial RTU that is meant for small applications. It contains all the features of a larger RTU that DPS has but comes with a smaller capacity and a cheaper price.

Always look for alarm monitoring system manufacturers that have your budget's best interest in mind. The only way for them to look out for your budget's best interest is if they have a flexible range of equipment solutions to offer, and can give you customizability in form factors.

Through the NetGuardian DIN, I was able to offer him PoE(Power over Ethernet) which is great for when you have limited wiring capabilities in settings such as pump rooms. The NetGuardian DIN would then be able to send this information to my client's master station.

My client wouldn't be able to use text-2-cell directly from the PoE NetGuardian DIN due to being Ethernet only and not having a cellular module. Instead, my client had to communicate this data with his alarm gather master station. This is possible due to DPS Telecom's ability to integrate into existing systems seamlessly, hence helping to set up our clients for future hassle-free scalability and integration.

Next, we made our client understand exactly how his Text-2-cell feature would work. My client could view his Text-2-Cell notifications on a web browser or straight to his email. To set this up so that he would receive messages directly to his phone's SMS, he needed to use his mobile provider's Email-To-SMS gateway.

An example of this would be if my client sent an email to (his-number-here)@(provider's email to text gateway domain here).com, he would receive a text of the exact contents of the email. The device would also send out SNMP traps to an SNMP manager which notifies the master station about what just occurred. The SMS messages that you receive will be free.

Finally, my client was ready to wrap things up and asked me about control relays, discrete inputs, and analog inputs for water tank levels. As I saw that my client was under the impression that things came under strict device specs, I made sure to let him know that DPS Telecom prides itself on being a very customizable-friendly alarm monitoring system manufacturing company.

If you are one of our clients or potentially a client, we want you to treat us like your own personal engineer. I told my client we could remove or add inputs, outputs, serial ports, etc. We would also be able to accommodate all his needs for customized form factors.

My client was also not in favor of a subscription type of deal, so I made sure he knew that it would be a one-time transaction with free tech support and firmware updates. This goes across the board for all DPS Telecom product installations.

I got on a web demonstration of our products and services that we would be providing our client with, and after he was fully satisfied. Here is a brief diagram of what the setup would look like (certain omissions were made so that we don't compromise our client's identity).

we sent over a quote and his shipment is en route to make his company scalable, reliable monitored, and supported by DPS Telecom experts.

If this story resonates with a current problem that you have, or if you have any further questions regarding this solution -- please reach out to me through email or a phone call (faster response times if you call).

Call today at 1-800-693-0351 or E-mail me at sales@dpstele.com

Ziad Alezabi

Ziad Alezabi is a Application Documentarian at DPS Telecom. He reviews successful DPS client projects and reports on the best practices that you can use to successfully reach your own project goals.