Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayStaying on top of freezer and refrigerator temperatures can be difficult, especially if you have multiple locations with a variety of cold storage systems. Installing a freezer monitoring system can provide assurance that your food or vaccines or other valuable items are stored safely and within the set temperature range.

Let me walk you through the basics of how freezer temperature monitoring works. We'll cover how you can use sensors, automated alerts (ex. email/SMS), and battery backup to provide 100% peace of mind.

Temperature sensors are the most important tool for freezer monitoring systems. With so many to choose from, though, how do you get started?

My background at DPS Telecom is, quite obviously, in the telecom space. I'm an expert in temperature monitoring, but refrigerator/freezer monitoring has a handful of differences that I had to learn and apply. Let's cover everything you need to think about when selecting a temperature sensor/probe for your freezer or refrigerator:

In my years in the remote monitoring space, I've learned to help my clients err on the side of additional sensors. When installing any kind of remote monitoring, the most expensive part of the project design is the first sensor. That requires a head unit, thinking about power, etc. Every additional sensor is a relatively small incremental expense that really improves the "site picture" you get when you look at your alerts and status screens.

In the context of monitoring the cold chain or miscellaneous cold storage applications, two primary sensors come to mind:

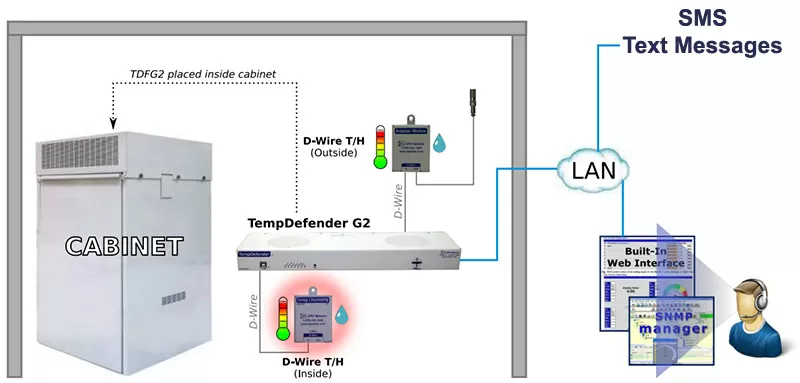

Once freezer temperatures and other values are monitored with sensors, you need some kind of "head unit" that collects that data and puts it onto your network (or notifies you through some other means). At DPS and in the general remote monitoring industry, we call these "RTUs" (Remote Telemetry/Terminal Units).

The freezer alarm with your head unit should be set to activate when temperatures, humidities, air flows, or other measured values fall outside acceptable ranges, ensuring any dangerous or unexpected changes are identified quickly. This can locally render as flashing lights or loud alert beeps.

Beyond those basics, your freezer monitoring system should be set up to provide some form remote temperature monitoring. This way, even if you are not at the site, you will be alerted by an instant alert when freezer temperatures fall out of your set "normal" range.

At DPS, several different types of automated alerts are typical for our clients:

Freezer temperature monitoring with automated alerts should be part of any cold storage plan to ensure products stay well within the set range and save you from unnecessary losses.

For added peace of mind, consider a freezer monitoring system that has built-in battery backup. This ensures the freezer temperature monitoring system runs for an extended amount of time even when power is out or other disruptions occur.

This is especially important when you consider that commercial power failures are one of the biggest threats to any continuous cold chain. You need you monitoring system the most precisely when power is lost.

Depending on the scale of your facility, it might be enough to have a DC-powered RTU that runs on your protected DC battery plant. If you don't have this option, even a simple AC UPS used to power desktop PCs during a power failure will have enough power to run a tiny monitoring device for hours and hours.

You can also consider built-in battery backups to make your monitoring device truly independent of outside power. At DPS, we've done this on occasion as a semi-custom device type when our clients have needed it.

Temperature monitoring in your freezer or refrigerator might not be the most complicated remote monitoring project I've ever had to work on, but it's also not terribly simple. There are problems that you can step right into if you've never done anything like this before on your own.

I'll give you guidance as you get started so that your project moves forward correctly.

For assistance choosing, buying, and installing the best possible freezer monitoring system, call me at 1-800-693-0351 or email me at sales@dpstele.com

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...