Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat Today

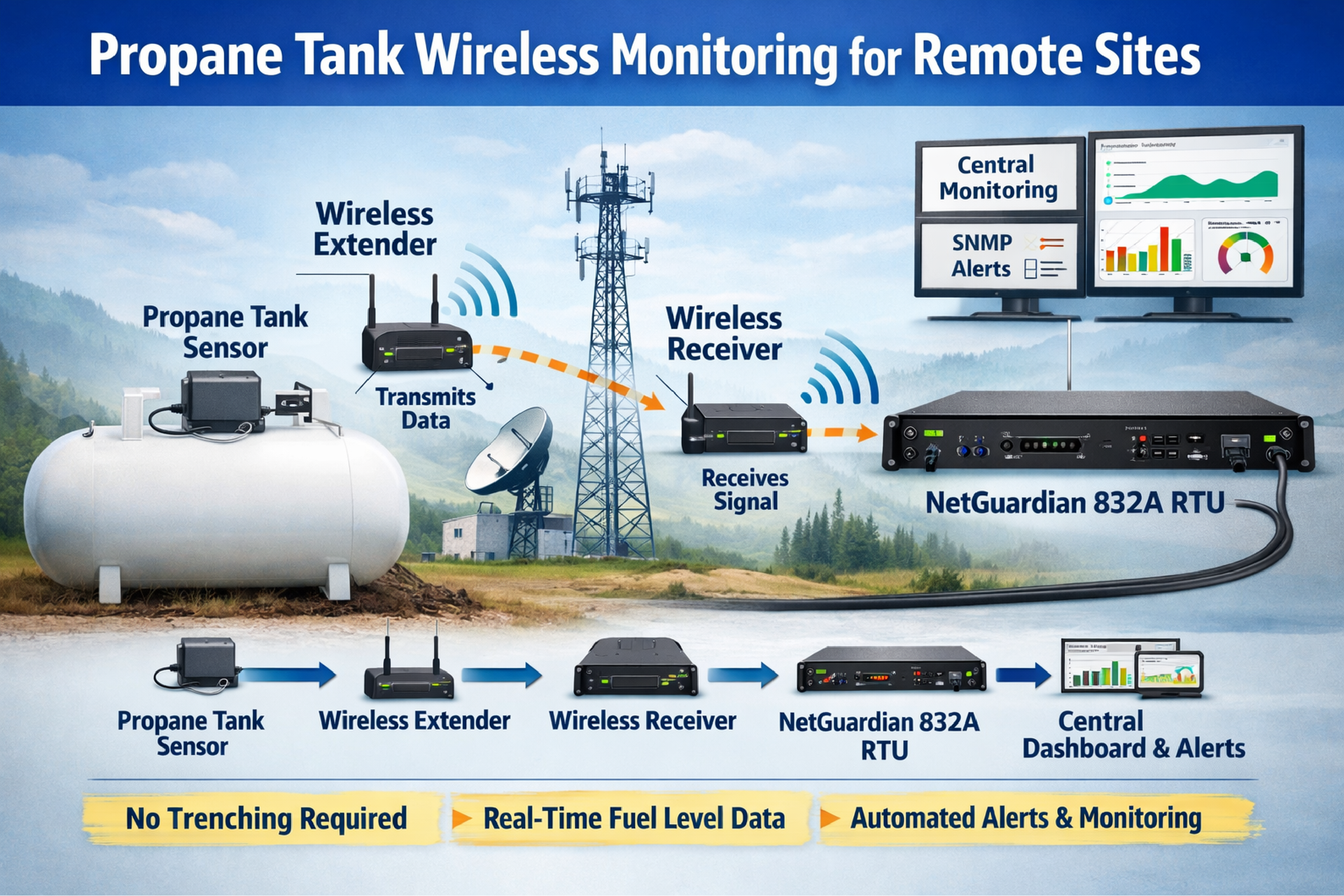

Propane tank wireless monitoring is a technology system that remotely tracks and reports the fuel level in propane tanks using wireless sensors and communication hardware. Instead of requiring manual readings, the system sends real-time data to centralized dashboards or alerting systems via wireless transmission.

In business environments this kind of propane monitoring improves efficiency, reduces labor, and prevents fuel shortages. It's especially impactful for those managing remote infrastructure like telecom sites, utilities, or industrial operations.

For a typical wireless propane monitoring system, the following components are used:

| Component | Role |

|---|---|

| Propane Tank Sensor | Detects the liquid propane level within the tank. |

| Wireless Extender | Transmits sensor data wirelessly across distances. |

| Wireless Receiver | Receives the data signal and interfaces with wired systems. |

| NetGuardian 832A RTU | Centralizes propane data with other alarm and environmental signals. |

This architecture allows real-time monitoring without trenching cables. This makes it ideal for rugged, remote, or urban environments where cable installation is cost-prohibitive and difficult to justify in your annual budgeting.

Manual or legacy monitoring systems come with several business risks:

Traditional sensors often require underground cables, which means:

Without real-time data:

Businesses often send technicians to remote sites for visual checks. This adds:

To maximize ROI and system reliability, follow these best practices:

Wireless propane monitoring is especially useful in industries and applications where remote operations are standard.

Wireless propane tank monitors deliver operational, financial, and safety advantages:

DPS Telecom offers an integrated wireless propane tank monitoring system that connects directly to its NetGuardian 832A RTU - the same platform used for environmental alarms and network fault management.

By choosing DPS, you eliminate complexity, gain centralized control, and reduce the risk of fuel-related service interruptions.

A wireless propane tank monitor is a device that remotely measures and reports the fuel level in a propane tank using a wireless communication system. It helps avoid wasteful visits to manually check fuel gauges and ensures continuous fuel visibility.

Businesses use wireless monitoring to reduce site visits, prevent fuel outages, improve safety, and streamline fuel delivery scheduling. It's especially useful for remote, critical, or unmanned sites.

The propane gas monitor uses a tank sensor connected to a wireless extender, which transmits data to a receiver. That receiver connects to an RTU (like the NetGuardian 832A from DPS Telecom) that integrates the data into a central monitoring platform.

Yes. The wireless topology from DPS Telecom eliminates the need for trenching by wirelessly bridging the gap between the tank sensor and central receiver.

You typically need a propane tank level sensor, a wireless extender, a wireless receiver, and a central RTU like the NetGuardian 832A from DPS Telecom.

We've helped network operators, utility companies, and remote facility managers get 24/7 fuel visibility without the headaches of traditional sensor installs. If you're ready for a propane monitoring system that works with your existing site monitoring gear, contact DPS Telecom today to schedule a tailored demo.

Call: 1-800-693-0351

Or email: sales@dpstele.com

Let your propane tanks report their levels - so you don't have to guess.

Andrew Erickson

Andrew Erickson is an Application Engineer at DPS Telecom, a manufacturer of semi-custom remote alarm monitoring systems based in Fresno, California. Andrew brings more than 19 years of experience building site monitoring solutions, developing intuitive user interfaces and documentation, and opt...