Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayVery commonly, someone will request an HVAC controller for controlling and monitoring cooling equipment. One of the main reasons that this may be such a desired application is that it minimizes and optimizes energy consumption.

First, you need to ask yourself how much control you want over each floor or AC unit in your facility.

If you want to have a system that controls the entire floor at the same temperature, it is a smaller operation. However, if you want to control each AC unit individually, it will be a larger installation.

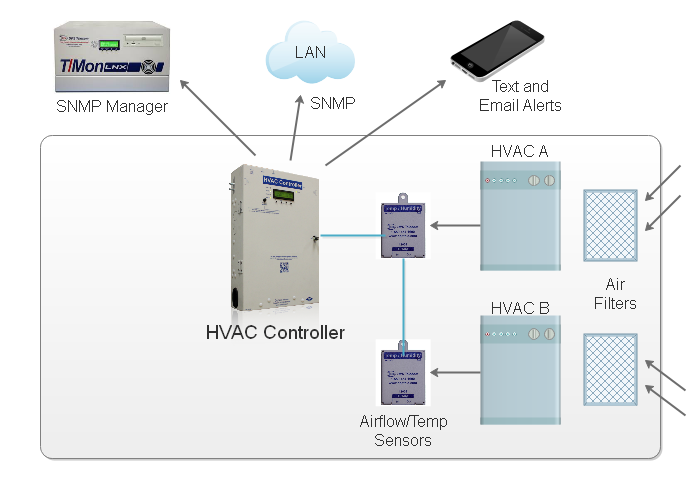

You also need to consider whether you want to control all of your units from one location. A good manufacturer will offer you HVAC controllers that can link up to a central monitoring system so that you can conveniently and efficiently operate out of one place.

I spoke with a client recently that had Air Handling Units (AHUs). These are control panels that control the temperature on each floor. My client said the following when I asked him how much control he had over his cooling system:

"On the level of control, the more fine-grained control we can muster, the better." - Client

I wanted to get specific about his AHUs. First, I needed to know what sort of vents the air handling units had. A smart way to monitor and control your air handling units would be through the flow detected through the vents.

My client then provided me with a helpful diagram that showed me he was working with Fan Coil Units (FCUs). A fan coil unit works in the following order:

My client had a pre-existing BMS capable of controlling the air vents, meaning there is something electronic on my client's site that I can control. It turned out that my client's BMS had power supplied to a servo motor that could open and close the vents.

Based on all the information my client provided me with, I was able to draw up a solution to allow him fine-grained control over his facility's cooling system. This utilized the existing BMS and servo motors controlling the vents by doing the following:

I made sure that the HVAC controller we installed was able to communicate with my client's building management system. To do this, I used the Modbus protocol to receive data and control commands.

Modbus is a communication protocol that is widely used in automating industrial applications. This allows devices to communicate through a master-slave structure.

I then installed flow sensors inside the supply ducts of each Fan Coil Unit (FCU) to monitor the rate of the airflow. This provides my client with real-time data on the air flowing through each unit.

After installing flow sensors, I installed an HVAC controller in my client's BMS to interpret the data being captured from the airflow sensors and adjust the servo motors controlling the vents according to the data it was receiving.

The HVAC controller will be used to calculate and adjust the vents to maintain temperatures on each floor. It continuously monitors and controls the temperatures at several locations thanks to a master station unit being tied to it.

The front-panel LCD is convenient and allows you to perform tests on each unit, configure controls and alarms, and check the status of each unit. When not in test mode, the display cycles through various screens displaying temperature readings, lead/lag status, and more. The HVAC Controller is easy to mount, wire, and use.

When you use the solution above, you can achieve "fine-grained" control over your cooling system. DPS Telecom prides itself on interfacing with your existing equipment so that you don't have to rip your entire system out and start over again.

In addition to our integration capabilities, we also offer on-site visits, in-person training, in-depth documentation, and tech support for all of our clients. We want our clients to know their products inside and out so that they can use them to their full extent.

When you know your equipment well and know how your infrastructure works, you will be able to use DPS Telecom as your own personal engineer.

If you would like clarification on this process that was not included in the article, or if you are thinking about doing business - reach out and I would be very happy to help you. Even if we can't find a compromise, I will do my best to point you in the correct direction.

Call today at 1-800-693-0351 or E-mail me at sales@dpstele.com

Ziad Alezabi

Ziad Alezabi is a Application Documentarian at DPS Telecom. He reviews successful DPS client projects and reports on the best practices that you can use to successfully reach your own project goals.