Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayMaintaining your remote site's performance, in the long run, is essential to guarantee the cost-efficiency of your network. A well-sustained site is the key for productivity and ensuring longer equipment lifespan, while also keeping your network's operational efficiency.

However, the costs of running a remote site are always increasing. It is more challenging than ever to balance your maintenance costs and site needs. The common strategies to reduce costs used to be very effective, but as technology evolves they are becoming less and less helpful.

One of the most efficient ways that network managers reduce maintenance costs is by deploying remote monitoring systems. Remote monitoring systems involve the collection of data from the equipment on-site, as well as the remote control of those equipment.

Let's take a look at some strategies for reducing maintenance costs using remote monitoring systems.

In your remote monitoring system, you'll have a remote telemetry unit (RTU). RTUs are small devices responsible for continuously gathering data from your mission-critical equipment at your remote sites.

The collected information is then passed on to your master station. One of the master station main roles is to give you the power of the predictive approach.

Competent master stations will provide you with the trend analysis capability, which allows you to know when you need to perform maintenance on your equipment. This is very important because reactive maintenance after something has happened or preventive maintenance when it's not really necessary are very expensive.

Predicting when maintenance is required means that you need to know exactly when a piece of gear is likely to fail - so you can address this problem before it actually happens. Your remote monitoring will be responsible for giving you the knowledge about your remote devices health and their expected performance.

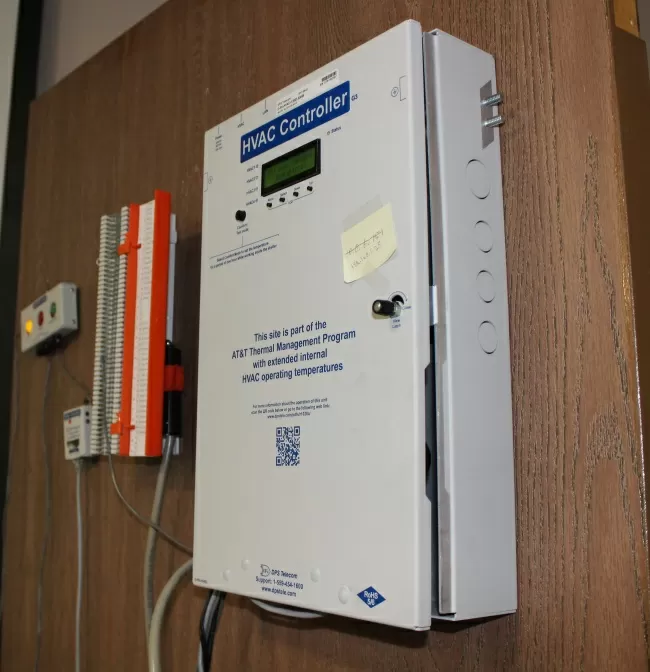

So, with the trend analysis provided by your master station you are able to plan maintenance schedules and equipment replacement. You can, for example, see gradual reductions in HVAC performance over multiple weeks or months.

Keep in mind that, although raw analog trend data is a good first step, you are still likely to miss something important. Your master station needs to use graphs to visually represent your equipment data, which can make trends and potential issues stand out.

In a nutshell, predictive maintenance helps prevent network failures in a timely manner. And this, ultimately, allows you to prioritize work and perform only the required maintenance and repairs when necessary.

When you analyze history reports and trends provided by your master station, you can also identify problem areas in your network. Examining network data over a period of time allows you to identify recurring conditions that you wouldn't be able to see by simply looking at an isolated alarm event.

Many companies rely on human intervention to analyze all of the alarm data though. And, often, it's difficult to diagnose the cause of network failures. What if, for example, different switches at different remote sites are reporting a connection loss, are these separate failures on separate lines or a single failure on a line connecting the two?

If you are monitoring these sites separately, it may take hours of patient testing to find the real cause. Experienced technicians will probably be able to diagnose the problem faster, but not every company has a 30-year veteran in their staff.

Having a master station with the root cause analysis capability is critical to have an automated process of data analysis. With a remote monitoring system that can automatically correlate repeated combination of alarms, you will be able to identify problem areas and eliminate recurring problems, that otherwise would bring maintenance expenses.

As you might already know, remote monitoring power supplies means that you'll be measuring the power usage and quality at your remote sites. And that's important to help you reduce maintenance costs because it assures you are using electric power efficiently.

Without a power monitoring system in place, your network is susceptible to power outages.

You may have a DC battery power plant for your mission-critical gear, but what about an alternate AC power for your air conditioning unit?

The one thing that many network managers forget to do is to provide backup power for the air conditioning units at their remote sites. And, the problem is, you still need air conditioning during a power outage.

Your rack-mounted equipment will keep running during an outage, but the site's temperature will keep rising - until it reaches a point of thermal shutdown. The thermal shutdown caused by a failed AC unit adds a lot of money to your maintenance expenses. Equipment in thermal shutdown can't be restarted until the temperature returns to normal (which can be long after the power outage is over), this negatively affects your gear health and your revenue.

Remember that your air conditioning unit is one of the main points you need to monitor in terms of maintenance. Keeping it running even at the most critical times is a best practice to reduce your maintenance costs - related to the AC unit itself and to your mission-critical equipment - and to assure the efficiency of your remote network operations.

When monitoring your remote site's power, keep in mind that backup batteries can't be completely drained of energy. If they do, they will be damaged permanently. Some battery-plants are completely integrated into the site and they power all primary gear, this can cause additional problems that make restoration even more complicated.

High temperatures cause by air conditioning failures will dramatically shorten the useful life of batteries. For instance, a lead-acid battery lasts around ten years if working under ordinary conditions. But, if it is always operating at temperatures above 122 F, it's lifespan will be reduced to only 1 year and a half.

Imagine the costs of telecom-quality batteries, and multiply that for the number of remote sites that presented the outage. Now, think about the striking business expense that this will become.

With proper monitoring, though, you can avoid all this trouble and expenses.

Your remote monitoring system will also need a reliable source of backup power, so you won't lose visibility over sites.

If your remote monitoring gear is down during a power outage, you won't be able to know what needs maintenance and how fast this needs to be done. Other tasks would be affected, such as:

All of these damages related to poor remote power monitoring add up to unnecessary costs. Not being able to avoid or to at least keep your equipment online during a power outage affects not only your gear health but your operations as well. Nevertheless, the true net effect is on your bottom line.

The financial effects of lack of power monitoring are:

Independently of the industry you are in, a remote monitoring system can reduce the hidden costs that come with maintaining your remote equipment. That's because anytime you send your techs to your remote sites to manually check on your gear takes time and money.

Using RTUs to collect data from your network is a far more efficient way of keeping an eye on your devices. Since your techs won't have to be present, the costs associated with sending them on long truck rolls to faraway sites are drastically reduced. They will only have to be sent out to your facilities when actual repairs and upkeep work is necessary.

As we've talked before, the RTUs will gather information and send it to your master station, so your team can access this data anywhere and at any time. Also, instead of having your techs visiting your sites to collect information about what is going on that particular day or period of time, your monitoring system will be gathering data continuously - which means you'll have better insights and situational awareness.

Your end result is a well-informed team, with more time to focus on other tasks and acting proactively any time an issue is spotted.

Another way that a remote monitoring system can help your techs to be more efficient is by giving them the ability to do maintenance tasks remotely.

When you choose an RTU that have control relays, you will be able to remotely activate just about any piece of equipment. Imagine how frustrating it must be for you and your tech when you need to send him to a remote site simply to flip a switch, for example.

It's great to be able to remote control devices, but the best practice here goes beyond that. With quality RTUs, these operations can be done automatically - requiring none of your attention.

In this case, you'll be able to configure your RTU to automatically activate a control relay whenever a specified condition is met. This way, you won't need to use your RTU's interface at all.

If, for example, the commercial power at your remote site fails and your backup batteries hit a pre-configured low threshold, your RTU would activate a relay and turn on the generator. This way, your remote monitoring system won't allow your site to go dark. Just make sure that your RTU will still be sending notifications for each alarm condition and for the relay activation.

Having a comprehensive knowledge of what is going on at your remote sites is critical to reducing your facility's maintenance expenses. And it all starts with a competent remote monitoring system.

Our whole line of RTUs and master stations was designed to provide you with up-to-the-minute information about any device or condition you wish to monitor. This detailed and precise information will ultimately help you implement efficient maintenance cost reduction strategies.

So, if you are seeking a remote monitoring manufacturer that will be more than simply a vendor, but also a partner, talk to us at DPS.

Morgana Siggins

Morgana Siggins is a marketing writer, content creator, and documentation specialist at DPS Telecom. She has created over 200 blog articles and videos sharing her years of experience in the remote monitoring industry.