Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat Today

Central Arizona Project (CAP) is Arizona's single largest resource for renewable water supplies. CAP brings 1.5 million acre-feet of water from the Colorado River to Central and Southern Arizona every year, serving more than 5 million people. Handling a job at this scale requires a 336-mile long system of aqueducts, tunnels, pumping plants, and pipelines.

Sean Parsons, Communications Engineer at CAP, sums up the value of remote monitoring this way:

"You can't have eyes on every piece of equipment, everywhere in the network, all at once without some kind of system to monitor those devices," he says. "You would have to have employees standing everywhere. You're going to need some kind of automated system."

An automated monitoring system gives you situational awareness of all your remote sites simultaneously.

"You need one place that you can go to and see what's going on with your equipment," Parsons explains. "You can see failures. You can see problems before they become failures."

A system that also gives you remote-control capability reduces wasted time and effort. You don't have to drive out to your remote facilities to manage them.

"The possibility of being able to make changes without having to go out and touch pieces of equipment directly adds value," says Parsons. "It cuts down on the number of man-hours it takes to maintain a system."

Like many utilities, CAP had a legacy monitoring system that still performed at a rudimentary level, but it wasn't truly getting the job done anymore.

"We have an older system that's still in place," Parsons says. "It's not our primary system any longer, so we are working on getting that cut over and making it a more robust and more thoroughly planned system."

CAP had purchased a modern T/Mon master station and new NetGuardian RTUs, but they hadn't yet completed the install.

"It was sitting in a rack underutilized," Parsons says. "We were told 'You already spent the money, so you guys better get it working."

Parsons was tasked with setting up the NetGuardians and wiring remote-site equipment into them.

"I was the new guy," he recalls, "They handed me a couple of 832As that had been decommissioned and said, 'Why don't you see if you can get this working and get these deployed?"

"So I began doing that. As we began integrating things, we more or less figured out how to use the units. We went to DPS HQ for Factory Training shortly thereafter," Parsons remembers. "Eventually it began to take off. As it became more and more successful for us, it began to build momentum. Now it's the primary system."

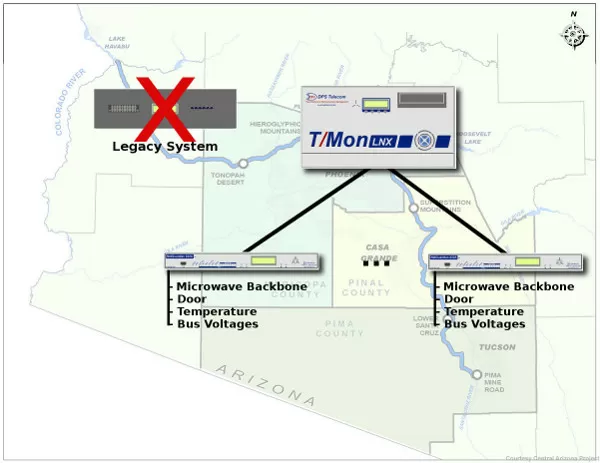

"We are primarily using the T/Mon now as our Master," he says. "We have NetGuardians at most of our larger facilities. We monitor our microwave backbone. We monitor our facilities themselves, too, so we can monitor if the door is open or closed. We can look at temperatures in the facility. We can monitor the bus voltages."

The key, for Parsons, is gaining remote visibility and control over devices where he otherwise can't. "We look at the ability to turn on and turn off the generators and a few other discrete points depending on the site," he says. "Primarily, if there's a piece of equipment where we don't have any other way to know what's going on, we'll hook it to the NetGuardians to be able to see what's going on."

Parsons recently attended DPS Advanced Factory Training in California. During class, he learned about newer T/Mon functions and SNMP configuration.

"I received the Basic Factory Training a while ago, and it was sufficient to get me started with the units. I understood how they worked," he says. "But recent software updates have added more functionality and changed the way the units are used. And we recently decided to implement SNMP. I didn't have enough training to utilize that. I really desperately wanted to get that piece of it."

Monitoring interfaces are used daily, usually by multiple people. That means they absolutely must be easy and straightforward to avoid wasting your time.

"The changes that DPS has recently implemented seemed to fill in all the gaps," Parsons says. "It seems like those things are a lot better planned out, and they require a lot less effort on my part as an engineer to figure out how to use them."

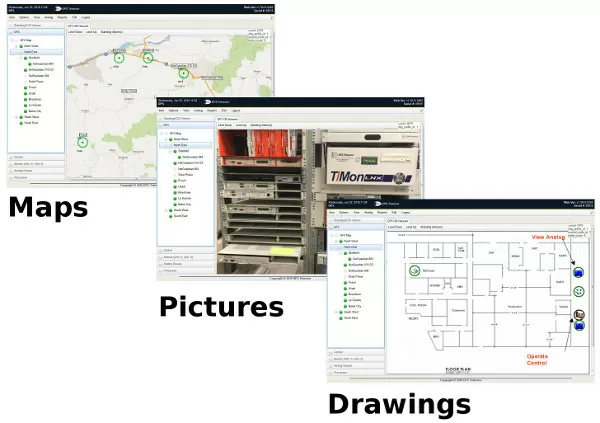

The Web GFX interface in T/Mon, which displays alarms as icons on top of maps, diagrams, and photographs, makes it easier for CAP's team of technicians to interpret new alarms.

"The graphics feature has a lot of potential to cut back on the required familiarity. A lot of our techs haven't been to all the sites. So, it's good to be able to use a photograph or rack elevation or illustrative diagram to point somebody to the failure," Parsons explains. "It goes beyond just 'There's a major failure, go there and figure it out.' I see that as useful to get people familiar with the sites and what's out there."

Parsons has his eye on improving remote visibility of his battery plants. Although this requires an investment in additional monitoring equipment, he sees big value in it.

"Most people oversimplify batteries," Parsons says. "They think it's just a battery: power goes in, power goes out, and there's nothing to it. They don't realize that batteries degrade over time. How long it takes a battery to degrade is directly proportional to how you take care of your batteries. So if you ignore them and you keep them in hot rooms and you don't take care of them, they fail in a few years. Usually, you don't see that failure until you depend on that battery and realize it's dead. Proactively monitoring your batteries and periodically doing capacity testing means that, at any given moment, you know how your batteries will perform."

"I know my site will stay up," he says with a grin. "Its a small investment up front that pays dividends on the back end."

At DPS, we receive many urgent quote requests after an earlier "Do Nothing" decision comes back to bite you. You have no reason not to be proactive (and maybe you'll manage to impress your boss).

Call us. Chat with an expert for 10 minutes. We'll email you a detailed quote with a custom application drawing. We'll even include a summary of business benefits you can use to justify your project budget.

Call 1-800-693-0351 now for your quote

(or send us a quick online message instead)