Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat Today

Twin Valley Telephone is a triple-play provider serving several counties in the Kansas area. The company has brought fiber directly to the homes of their customers.

As a telephone company, outages pose a huge threat to Twin Valley. Their customers rely on consistent uptime, and so does their bottom line. Twin Valley's technicians have to pick up the slack if systems go down. "If we have a major outage, we stay until it's fixed," said Aaron Oehmke, a Network Technician for Twin Valley.

"If you have something already set to let you know of an outage, it's cost savings for time spent troubleshooting, truck rolls - somebody going to look at a specific site."

Remote monitoring of network infrastructure keeps both customers and employees happy. "To me, detecting and fixing an outage situation is the biggest benefit," said Oehmke. "Without the monitoring, you don't know about it until a customer calls in and says their services are out. It becomes a trend when you have more than one customer call in, and then you can start look to where that problem is. With good monitoring, that doesn't happen."

Truck rolls are also a concern for Twin Valley, because their territory covers a large area. "From corner to corner, it's probably an hour-and-forty-five minute drive," said Oehmke. "There's definitely a long stretch in between." The longer it takes to get out to a site, the longer it takes to fix a problem.

According to Oehmke, having a monitoring system in place is just smart business sense. "If you have something already set to let you know of an outage, it's a cost savings for time spent troubleshooting and on truck rolls - somebody going to look at a specific site."

"I love that. I've got what I'm going to be mounting, I've got my power feed, I've got my wires, I've got my network connectivity and I've got all my alarm points."

Recently, Twin Valley swapped out some of their equipment. "We upgraded to different access gear," said Oehmke. "We went from one vender to another, giving us more options."

That new gear present the opportunity to improve their monitoring system.

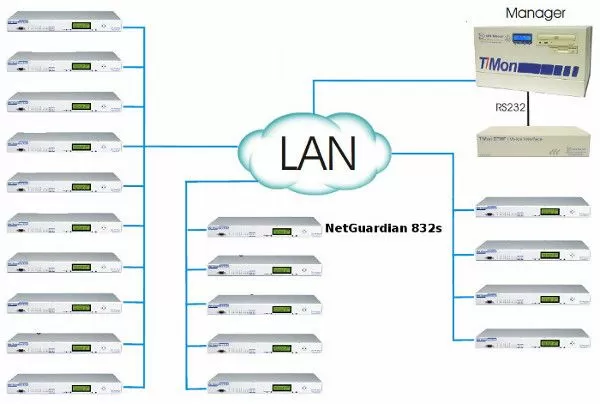

Twin Valley is constantly trying to improve their monitoring efforts, finding new uses for their T/Mon regularly. "This week we actually removed a rack in the office, pinched a fiber jumper, didn't see that it was broken, and the internet went down," said Oehmke. "It was not monitored through the T/Mon, so that was brought up already. We're going to add that in."

"As far as I'm concerned, you can train everyone else with the web interface, way easier."

New to his position, Oehmke attended DPS factory training to get the training necessary to make the most of their DPS monitoring equipment. "I have to dig through what someone else has completely done to figure out what I'm even thinking I want to do," said Oehmke. "I highly doubt we are utilizing what this is capable of."

DPS factory training gave Oehmke the chance to experiment with equipment in a controlled environment. "I love that. I've got what I'm going to be mounting, I've got my power feed, I've got my wires, I've got my network connectivity and I've got all my alarm points," said Oehmke. "I like that."

Oehmke was able to experience all that their equipment was capable of, including the easy web interface. "As far as I'm concerned, you can train everyone with the web interface, way easier," said Oehmke. "It's all new to me, but there's definitely some stuff I like."

Oehmke had some understandable reservations about inheriting a network that was built by someone else. "The thing I'm nervous about in my case is applying what I've learned now to what was built 7 years ago." said Oehmke.

Luckily for Oehmke, support resources are readily available. DPS technology is constantly evolving, but 24/7 tech support, factory training, and web resources are all available to help him apply what he learned in Twin Valley's network.

At DPS, we receive many urgent quote requests after an earlier "Do Nothing" decision comes back to bite you. You have no reason not to be proactive (and maybe you'll manage to impress your boss).

Call us. Chat with an expert for 10 minutes. We'll email you a detailed quote with a custom application drawing. We'll even include a summary of business benefits you can use to justify your project budget.

Call 1-800-693-0351 now for your quote

(or send us a quick online message instead)