Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayMunicipal utility prevents failures with centralized monitoring

| Field | Details |

|---|---|

| Industry | Electric and Water Utilities |

| Company Type | Municipal utility serving Orlando, FL |

| Geography/Coverage | Residential and commercial customers |

| Primary Challenge | No visibility into equipment failures at substations |

| Solution Deployed | T/Mon Master Station with NetGuardian RTUs |

| Key Result | Early detection prevented multiple infrastructure failures |

| Products Used | T/Mon Master Station, NetGuardian RTUs, sensors |

Orlando Utilities Commission has served Orlando's residential and commercial customers for 90 years. OUC won the award for most reliable electric utility in the Southeastern United States. By deploying DPS Telecom monitoring solutions, the utility maintains reliable service to customers.

OUC had no reliable way to monitor critical equipment at remote substations. When fans failed, doors were left open, or cooling systems went down, the utility had no visibility until equipment damage occurred. Communications Technician Duane Gunsch had experience with older monitoring gear that couldn't report the equipment status they needed.

"We would have never had any idea about a fan failing with the other system we were looking at," said Communications Technician Bob Anderson.

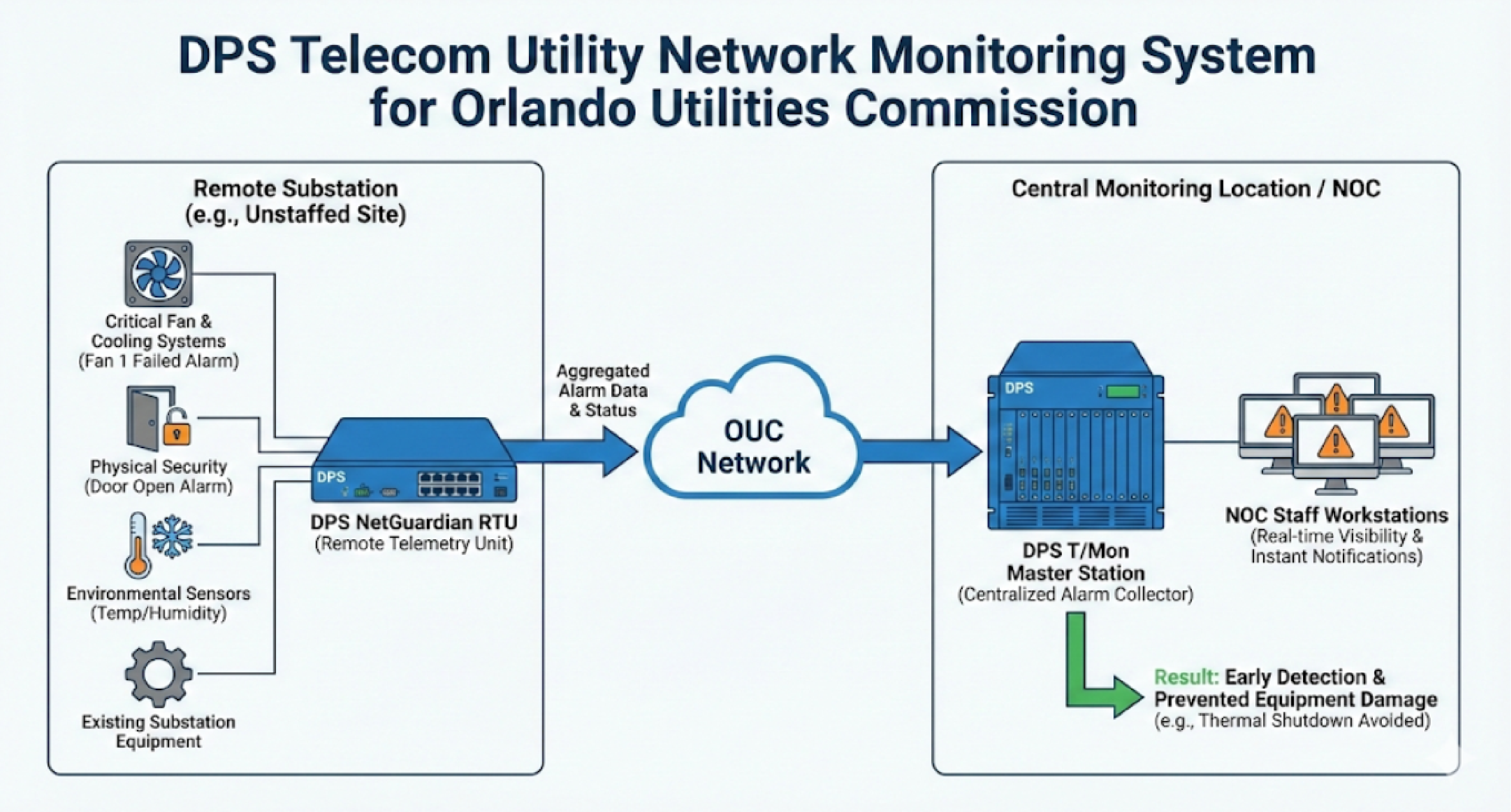

OUC deployed a T/Mon Master Station to centralize alarm collection from equipment throughout their network. The system integrates with NetGuardian RTUs deployed at substations. RTUs monitor doors, fans, cooling systems, and other infrastructure at each site.

Products & Services Used in This Solution:

T/Mon's multi-protocol flexibility was essential for this deployment. The system could integrate with OUC's existing infrastructure without expensive equipment replacements. This saved both time and money compared to a forklift upgrade approach.

Initial System Deployment OUC installed T/Mon and NetGuardian RTUs at substations. The system began collecting alarms from equipment across their network.

Factory Training Anderson and Gunsch attended DPS Factory Training in April 2012 at DPS headquarters in Fresno, California. They learned directly from DPS engineers.

System Optimization After training, the team returned to maximize their T/Mon capabilities. "The T/Mon is a brand new system for us, and we have very high hopes for it," Gunsch said.

The monitoring system proved its value immediately by preventing serious problems. When a door was left open at an unstaffed substation, T/Mon alerted OUC. "We went out there and saw the door was open with nobody out there," Gunsch explained. "It helped us identify and jump on something that could have been a bad situation."

Prevented Equipment Damage Early fan failure detection avoided thermal shutdowns that could have destroyed expensive gear.

Improved Security Response Door alarms caught unauthorized or accidental facility access before incidents occurred.

Protected Critical Infrastructure Cooling system alerts prevented equipment overheating at remote substations.

Centralized Network Visibility Single platform consolidated all network monitoring into one interface for NOC staff.

"We would have never had any idea about a fan failing with the other system. DPS was the only solution that could report that to us."

Bob Anderson, Communications Technician, Orlando Utilities Commission

Proactive Failure Prevention Early detection catches problems before they cause equipment damage or service interruptions.

Multi-Protocol Integration Value Existing infrastructure continued operating while adding comprehensive monitoring capabilities.

Training Investment Payoff Direct education from manufacturer engineers maximized system effectiveness and staff confidence.

T/Mon Master Station Centralized alarm management with multi-protocol support and web interface.

NetGuardian RTUs Remote telemetry units for monitoring equipment at substations and remote sites.

How do utilities monitor remote substations without constant site visits? Remote telemetry units like NetGuardians collect alarm data from equipment and sensors at each site. The data flows to a central system like T/Mon. NOC staff get real-time visibility into all locations from one interface. This eliminates manual site checks and provides immediate notification when issues arise.

What happens when legacy monitoring equipment can no longer report critical alarms? Many older systems use proprietary protocols that can't integrate with modern equipment. DPS T/Mon supports 30+ protocols. This allows utilities to continue using existing gear while adding new monitoring. It extends infrastructure life and avoids costly forklift upgrades. OUC kept their existing equipment and gained better visibility.

Can monitoring systems work with equipment from multiple manufacturers? Yes. T/Mon's multi-protocol support collects data from diverse equipment regardless of manufacturer. Utilities can monitor rectifiers from one vendor, generators from another, and HVAC systems from a third. Everything reports to one centralized platform. NetGuardian RTUs also support multiple protocols to accommodate mixed-vendor environments.

How quickly can utilities respond to equipment failures with centralized monitoring? Immediate alarm notifications let utilities respond within minutes instead of hours or days. Early detection prevents small problems from becoming major incidents. OUC caught a fan failure early. This avoided thermal equipment damage that could have cost tens of thousands in repairs and customer outages.

Centralized monitoring protects your infrastructure and prevents costly outages. Get started with a free consultation to discuss your specific monitoring needs.

Get a Free Consultation | Call 800-693-0351