Check out our White Paper Series!

A complete library of helpful advice and survival guides for every aspect of system monitoring and control.

1-800-693-0351

Have a specific question? Ask our team of expert engineers and get a specific answer!

Sign up for the next DPS Factory Training!

Whether you're new to our equipment or you've used it for years, DPS factory training is the best way to get more from your monitoring.

Reserve Your Seat TodayFactory training reduced response times at this nuclear power plant

| Field | Details |

|---|---|

| Industry | Power Generation/Utilities |

| Company Type | Public power supplier serving municipalities |

| Geography/Coverage | Pacific Northwest (Washington state) |

| Primary Challenge | Limited trained staff for 24/7 monitoring coverage |

| Solution Deployed | Multi-day intensive factory training program |

| Key Result | Multiple staff trained on all T/Mon system features |

| Products Used | T/Mon multiprotocol network alarm manager |

Energy Northwest is a leading power supplier serving the Northwest public power community for nearly 50 years. Headquartered north of Richland, Washington, they provide electricity at cost to public power utilities and municipalities. Their diverse workforce includes electricians, project managers, nuclear operators, accountants, pipe fitters, and engineers, all depending on reliable network monitoring systems from DPS Telecom to maintain critical infrastructure.

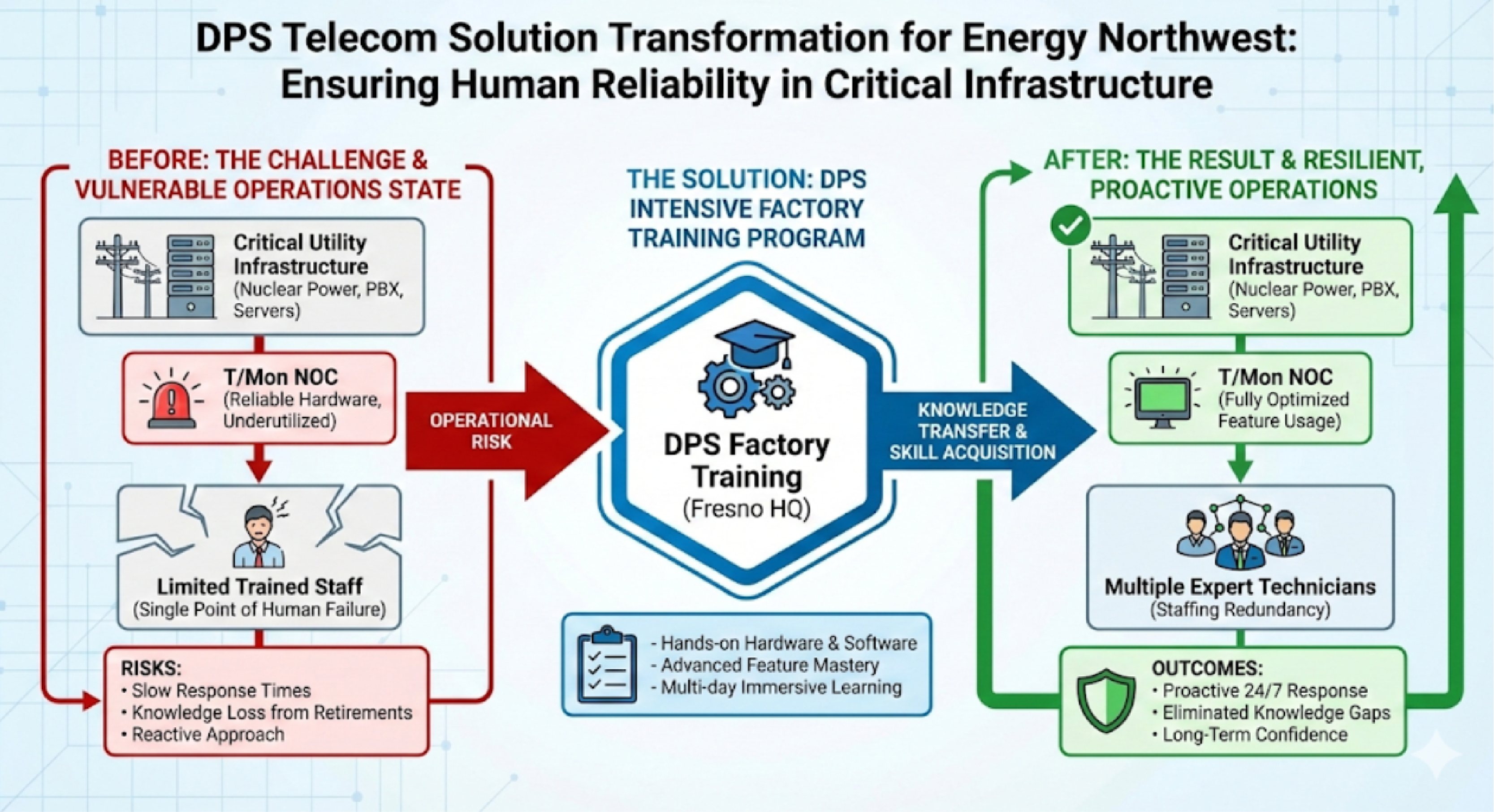

Energy Northwest faced a critical staffing challenge at their nuclear power plant. While their T/Mon NOC was performing reliably, they had only a limited number of trained technicians who understood the network monitoring system. When key personnel were on vacation or otherwise unavailable, response times suffered. In an environment where network server and PBX uptime must be constantly monitored, this shortage of trained staff posed a significant operational risk.

"Our response times can make or break our department and our company. We've been concentrating on response times for any piece of equipment that goes down."

Tim King, Technician, Energy Northwest

Energy Northwest enrolled staff in DPS Telecom's factory training program at company headquarters in Fresno, California. The multi-day intensive training covered all aspects of their T/Mon alarm monitoring system, providing hands-on experience with both hardware and software in a concentrated learning environment.

The training exposed King to T/Mon features he wouldn't have discovered through self-guided learning. "I understood alarms, but I wanted to learn what all the different DPS products could do," King explained. This comprehensive approach ensured staff could utilize the full capabilities of their monitoring system.

Energy Northwest successfully trained additional staff to monitor their critical network infrastructure, transforming their approach from reactive to proactive. The comprehensive training equipped their team to respond quickly and effectively to any equipment issues, eliminating the single point of failure risk they previously faced. Staff now have confidence using the full capabilities of their remote monitoring system.

Staffing Risk Eliminated Multiple technicians now trained for continuous 24/7 coverage

Feature Utilization Maximized Staff learned advanced T/Mon capabilities beyond basic operation

Knowledge Retention Improved Training provided lasting knowledge for future troubleshooting needs

Ongoing Partnership Established Confidence in continued access to responsive engineering support

"The training gives you information that you are going to remember later when you need it."

Tim King, Technician, Energy Northwest

| Benefit | Description |

|---|---|

| Rapid Staff Development | Multi-day intensive program prepared multiple staff members quickly and effectively |

| Comprehensive System Knowledge | Staff learned advanced features and capabilities beyond basic alarm monitoring |

| Long-Term Knowledge Retention | Training provided information staff remember when needed for troubleshooting |

| Continued Engineering Support | Ongoing access to responsive technical support from DPS engineering team |

Central hub supporting 30+ protocols including SNMP, DNP3, and Modbus.

How long does it take to train staff on network monitoring systems?

DPS factory training is a multi-day intensive program conducted at our Fresno headquarters that provides comprehensive knowledge in a concentrated timeframe. This structured approach is significantly faster than learning on your own while managing the steep learning curve of complex multiprotocol monitoring systems. Staff gain hands-on experience with both hardware and software, ensuring they understand not just basic functions but advanced capabilities they can leverage for your specific critical infrastructure monitoring needs.

What if our key monitoring staff retire or leave?

Cross-training multiple staff members through factory training ensures you always have qualified operators available, eliminating single points of failure in your operations. DPS training makes it possible to quickly bring new staff up to speed on all system features and capabilities, even advanced functions that might take months to discover through independent learning. This approach protects your organization's operational knowledge and ensures continuity when personnel changes occur, whether through retirement, promotion, or unexpected departures.

Can training cover advanced features we're not currently using?

Yes. Factory training exposes your team to the full range of system capabilities, including features you may not have implemented yet. This comprehensive approach helps you maximize your monitoring investment by revealing capabilities that can address operational challenges or improve efficiency. Many clients discover valuable features during training that they immediately implement upon returning to their facilities. The training ensures you're getting the most value from your equipment, not just using basic functions.

What ongoing support is available after training?

DPS provides engineering-level technical support with direct access to experienced engineers, not call center representatives reading from scripts. When you call, you speak with the people who designed and built your equipment. Many of our support engineers have decades of experience with DPS products and can provide practical solutions to real-world challenges. This ongoing relationship ensures you have expert assistance whenever you need it, giving you confidence that help is available 24/7 for critical situations.

Don't let limited trained staff become a single point of failure in your network monitoring. DPS factory training provides the comprehensive knowledge your team needs to maintain critical infrastructure.

Or call us: 1-800-693-0351